As drones become more sophisticated and capable, their performance and reliability increasingly hinge on effective thermal management. From high-performance computing to extended flight times, drones face significant challenges in heat dissipation. Efficient thermal solutions are critical for ensuring optimal operation and longevity of these airborne devices. This solution outlines the application of thermally conductive materials to manage and dissipate heat effectively in drone systems.

The Importance of Thermal Management in Drones

Drones are equipped with a range of electronic components, including processors, batteries, and sensors, all of which generate heat during operation. Excessive heat can impair performance, reduce efficiency, and shorten the lifespan of components. Effective thermal management is essential to prevent overheating, ensure system stability, and enhance the overall performance of the drone.

Thermal Conductive Materials: Key Players in Heat Management

Thermal conductive materials play a crucial role in managing and dissipating heat in drone systems. These materials facilitate efficient heat transfer from sensitive components to heat sinks or other cooling mechanisms. To address the heat dissipation needs, Fehonda, as a professional thermal conductive material manufacturer, recommends the following types of thermal conductive materials for you:

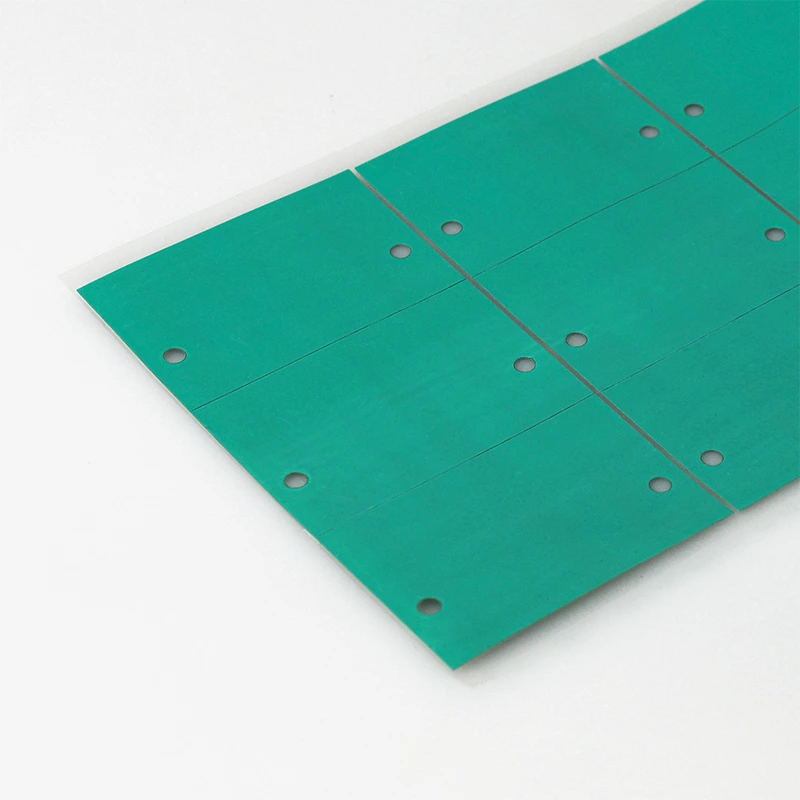

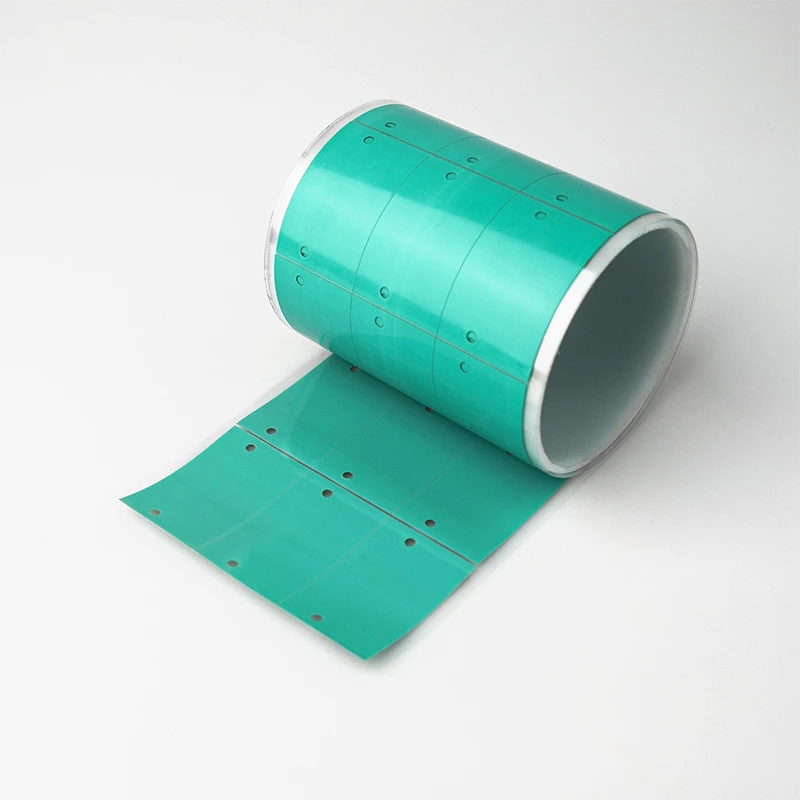

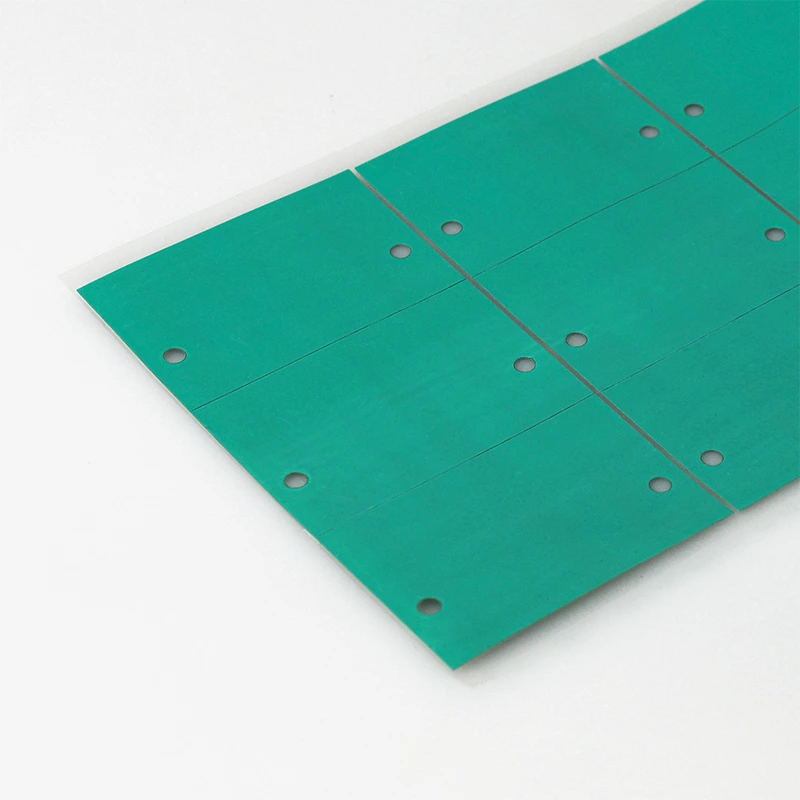

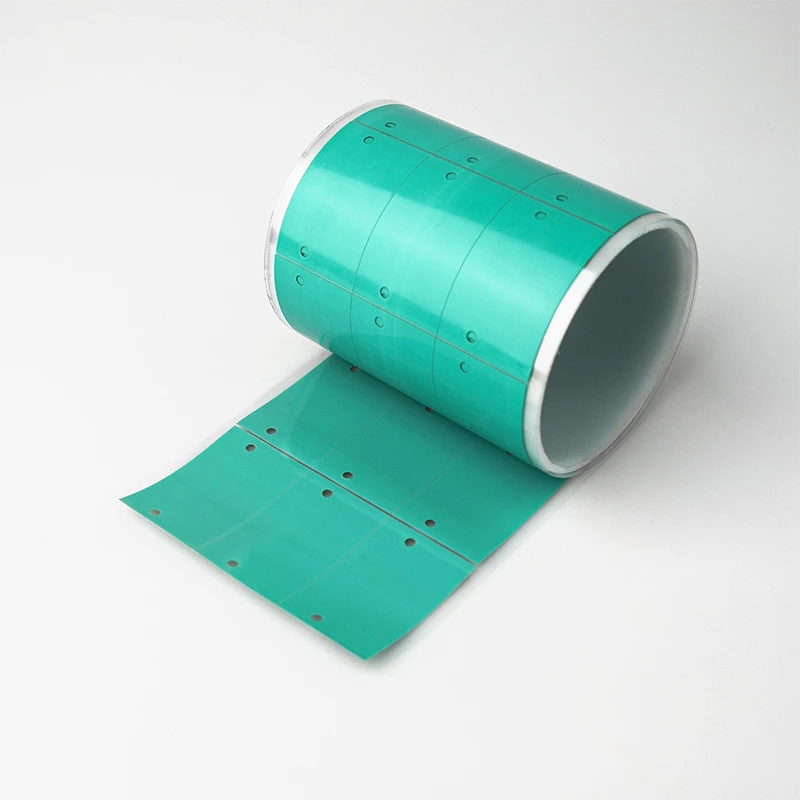

Thermal Pads

Description: Thermal pads are flexible, compressible materials that provide effective thermal conductivity between electronic components and heat sinks. Made from materials like silicone infused with thermal fillers, these pads can conform to irregular surfaces, ensuring maximum contact and efficient heat transfer. Their ease of application and versatility make them a popular choice for drone manufacturers.

Application:

Place thermal pads between heat-generating components (e.g., processors or batteries) and heat sinks or other cooling structures. Ensure pads conform to component surfaces for effective thermal contact.

Features and Advantages:

- Thermal conductivity of Fehonda thermal pads: 18W/mk

- Low thermal resistance, excellent thermal conductivity, good weather resistance

- Self-adhesive, good fit, easy to apply and remove

- Soft, good compressibility, high reliability in long-term use

- UL94 V-0 flame retardant, meets RoHS environmental protection requirements

- Conforms to irregular surfaces for optimal contact

Thermal Grease

Description: Thermal grease, also known as thermal paste, is a high-performance material used to enhance thermal contact between surfaces. It is typically applied between the CPU or GPU and the heat sink to fill microscopic gaps and improve heat conduction. Thermal grease is ideal for applications where precise heat management is crucial, such as in high-performance drone processors.

Application:

Apply thermal grease between the processor/GPU and the heat sink. Ensure an even, thin layer to maximize thermal conductivity.

Features and Advantages:

- Thermal conductivity of Fehonda thermal grease: 1-14.8W/mK

- Excellent thermal conductivity, high stability, excellent wetting performance

- Low thermal resistance, easy construction, and a very thin interface layer is formed on the rough surface

- UL94 V-0 flame retardant, meets RoHS environmental protection requirements

Thermal Gel

Description: Thermal gel is a paste-like gap-filling thermal conductive material that can be cured at room temperature or high temperature. After curing, it appears as a flexible rubber elastomer. Thermal gel has the characteristics of excellent surface conformability and is suitable for contact surfaces with microscopic unevenness. The gel is formed with the shape of the structure and can be used to fully fill the gap. Since the product has the characteristics of excellent insulation, pressure resistance, and high and low temperature resistance, it shows high reliability when used for a long time. In addition, it can also be used for automatic dispensing to achieve automated operations.

Application:

Using thermal gel between the motherboard and the heat sink to conduct heat can improve the overall reliability of the drone.

Features and Advantages:

- Thermal conductivity of Fehonda thermal gel: 2-8W/mK

- Excellent weather resistance, high and low temperature resistance, and insulation

- No sedimentation, no flow, it can be used to fill uneven gaps and can be used for automated dispensing

- UL94 V-0 flame retardant, meets RoHS environmental protection requirements

Phase Change Material (PCM)

Description: Phase Change Material (PCM) absorbs and releases heat as they transition between solid and liquid states. The material can help regulate temperature fluctuations and provide thermal buffering for drones. PCM is particularly useful in applications where maintaining a stable temperature is critical, such as in battery management systems.

Application:

Embed PCM in areas with significant temperature variation, such as near battery packs. Use PCM in conjunction with other cooling solutions for enhanced temperature stability.

Features and Advantages:

- Thermal conductivity of Fehonda phase change material: 8.5W/mK

- Phase change from solid state to liquid state occurs at 52℃

- Low thermal resistance, excellent thermal conductivity and heat dissipation, great reliability

- UL94 V-0, meets RoHS environmental protection requirements

- Provides thermal buffering and stabilizes temperatures

- Useful for applications with varying heat generation

Integrating Thermal Solutions in Drone Design

Effective thermal management requires careful integration of various materials and components into the drone’s design. Here are some considerations for optimizing thermal solutions:

- Component Layout: Strategically positioning heat-sensitive components away from heat sources and ensuring adequate spacing can improve heat dissipation.

- Material Selection: Choosing the right combination of thermal pads, thermal grease, thermal gel and phase change materials based on the specific heat generation and dissipation needs of each component.

Future Trends in Drone Thermal Management

As drone technology continues to advance, the demand for more efficient and compact thermal solutions is likely to grow. Future trends may include the development of advanced materials with higher thermal conductivity and innovative designs for integrating thermal management into compact drone platforms.

Conclusion

Effective thermal management is essential for maximizing the performance and reliability of drones. By utilizing a range of thermally conductive materials—such as thermal pads, thermal grease, thermal gel and phase change materials—drone manufacturers can address heat dissipation challenges and ensure the longevity and efficiency of their products. As drone technology evolves, continued innovation in thermal solutions will play a crucial role in supporting the next generation of high-performance, reliable drones.