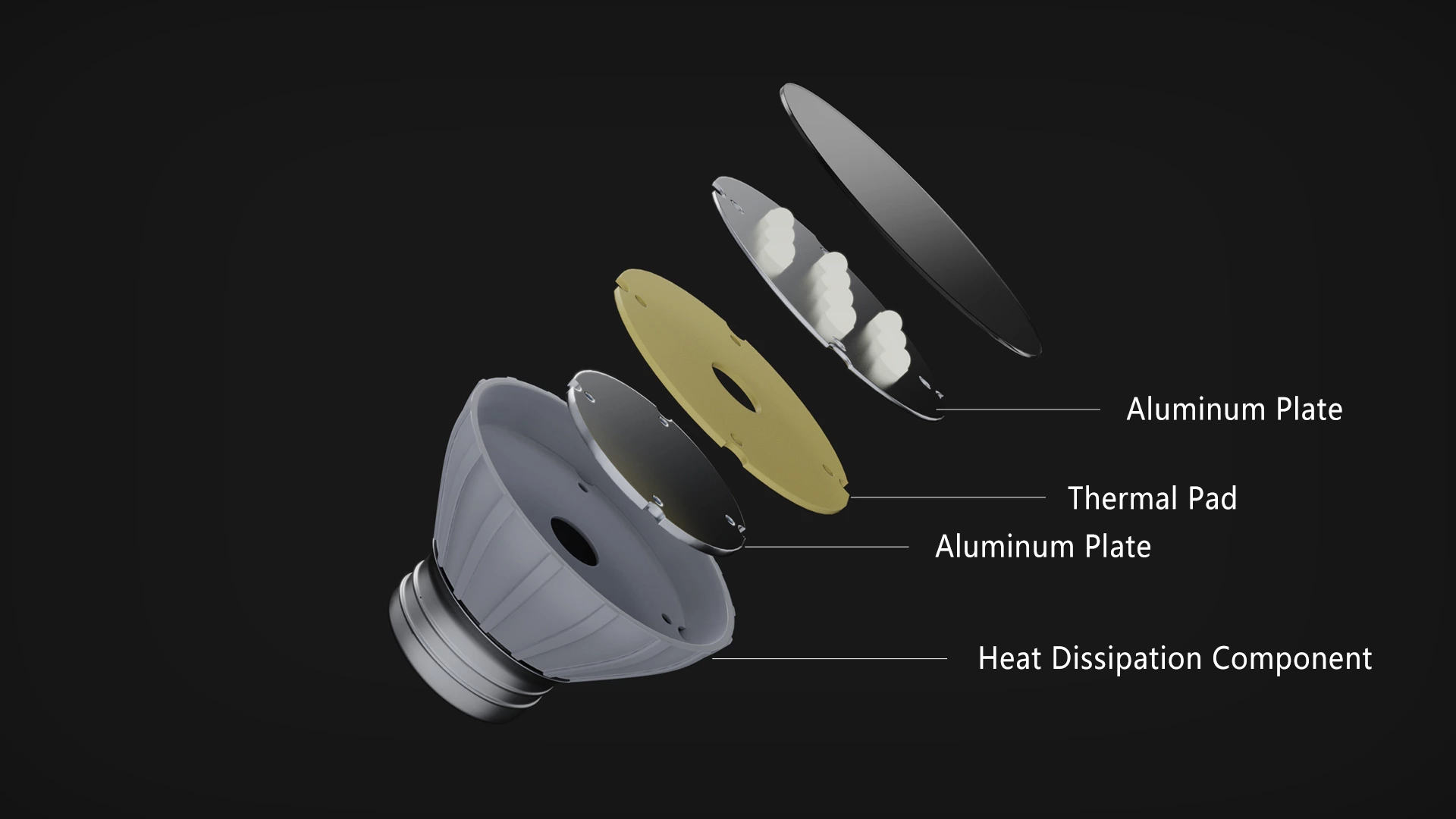

The reason why the LED bulb heats up is because the electric energy is not all converted into light energy, but part of it is converted into heat energy. So we need to quickly conduct this part of heat energy to the LED lamp housing. FEHONDA thermal pads can quickly and effectively transfer heat to heat dissipation devices due to their good thermal conductivity and fit. The internal temperature of the lamp is reduced accordingly, thereby prolonging the life and stability of the LED lamp.The internal temperature of the lamp is reduced accordingly, thereby prolonging the life and stability of the LED lamp.

LED Lamp Heat Solution

LED Lamps

As a semiconductor optoelectronic device, LED is widely recognized in the market. LED has the characteristics of small size, low power consumption, long life and environmental protection, so it has become an ideal solid-state energy-saving lighting source. However, as LED lamps develop towards high light intensity and high power, the problem of high-power LED packaging has gradually become prominent and has become the research focus in recent years.

Since the power density of the chip is very high, but the heat dissipation efficiency of the chip has not been improved synchronously, the heat dissipation problem of the LED is caused. This directly affects the performance and life of the LED. Especially in high-power LED packaging, the complexity of the structure and process makes this problem more serious.

However, the performance of LED is closely related to temperature. Too high temperature may cause many problems, such as decreased light efficiency, increased light decay, phosphor aging, reduced life, wavelength and color temperature changes, color coordinate drift, etc., and affect the normal operation of lamps. Therefore, solving the LED heat dissipation problem is crucial to improving LED performance and extending its life.

The Role of Thermal Conductive Materials in LED Heat Dissipation

Thermal conductive materials are a type of material that can effectively transfer heat and are often used to fill and coat the heat dissipation structure of LED lamps. Its' main functions include:

- Improve heat conduction efficiency

Thermal conductive materials can quickly transfer the heat generated by the LED, avoid local overheating and improve the overall heat conduction efficiency.

- Filling tiny gaps

There are some tiny gaps in the LED lamp structure and thermal conductive materials can fill these gaps to ensure that heat can be effectively transferred to the heat dissipation structure.

- Maintain stable performance

Thermal conductive materials help maintain the stable performance of LED lights and prevent problems such as reduced light efficiency and increased light decay caused by overheating.

Solution

In order to solve the thermal management problem in LED lighting, it is crucial to choose the appropriate thermal management material. With the advancement of LED technology, LED light sources are developing towards high efficiency, high brightness, high current density and small package size. The application of LED matrix is also becoming increasingly popular, which poses a higher challenge to the heat dissipation system. Therefore, Fehonda thermal conductive material manufacturer recommends: thermal pad, thermal grease, thermal conductive silicone, thermal conductive potting glue and other materials that can adapt to the different structural designs of LED lamps, reduce interface thermal resistance, and increase the service life of LED.

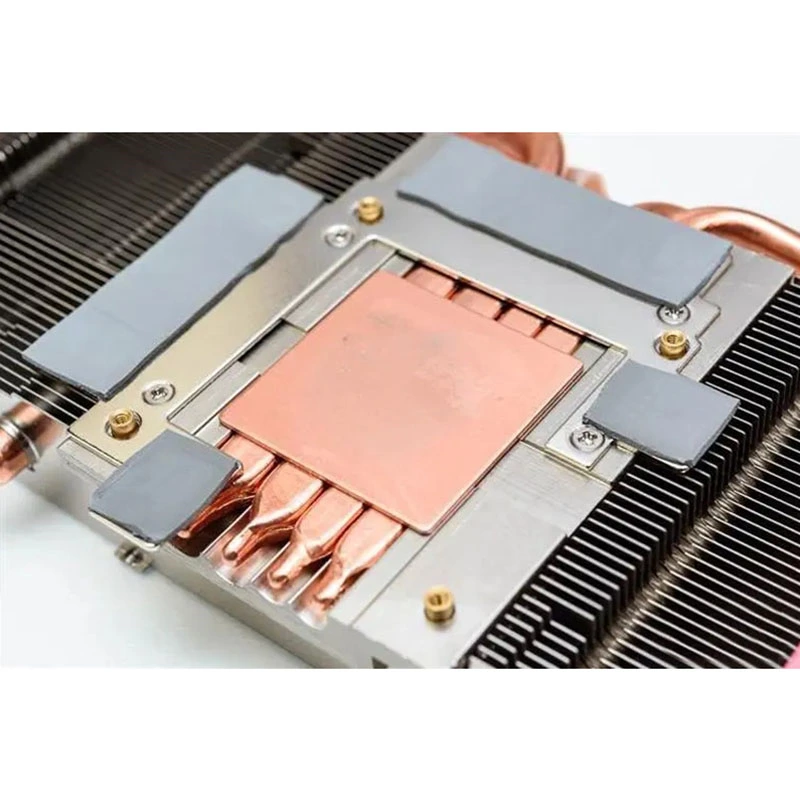

Thermal Pad

Thermal pad has good thermal conductivity and conformability and it can quickly and effectively transfer the heat energy generated by the LED to the heat sink. As a connecting medium, the thermal pad can fill the gaps in the connecting surface, which can improve the heat conduction efficiency between the LED and the heat sink and ensure that the LED components can quickly dissipate heat and maintain a stable working state.

For LED components of different shapes and sizes, Fehonda can provide customized thermal pads to meet customers' special needs in the field of LED lighting. We can also provide customers with better product heat dissipation solutions.

Features and Advantages

- Thermal conductivity of Fehonda thermal pad: 1.5-10.0W/mk

- Low thermal resistance, excellent thermal conductivity, strong weather resistance

- Self-adhesive, good fit, easy to assemble

- Soft, good compressibility, high reliability in long-term use

- UL94 V-0 flame retardant, meets RoHS environmental protection requirements

Thermal Grease

Thermal grease has excellent thermal conductivity, good lubricity and electrical insulation, and can quickly transfer heat from LED devices to achieve good temperature control. In addition, thermal grease has low viscosity and good application performance. It can be placed on the heating device by dispensing, printing, etc.

Features and Advantages

- Thermal conductivity of Fehonda thermal grease: 1-14.8W/mK

- Excellent thermal conductivity, high stability, excellent wetting performance

- Low thermal resistance, easy construction, and a very thin interface layer is formed on the rough surface

- UL94 V-0 flame retardant, meets RoHS environmental protection requirements

Thermal Conductive Silicone Rubber

Thermal conductive silicone rubber is a single-component, heat-conductive viscous liquid that can cure at room temperature. In other words, it is a paste-like silicone sealant that is resistant to stretching, vibration and impact. It is widely used in LED lamps. When encountering uneven internal components or small-sized components, thermal conductive silicone rubber should be used for filling and heat conduction. The function is to transfer the heat of the working aluminum substrate to the bottom of the LED lamp shell.

Features and Advantages

- Thermal conductivity of Fehonda thermal conductive silicone rubber: 1-3W/mK

- Anti-cold and hot alternation performance, aging resistance, high electrical insulation

- Excellent moisture-proof, tensile resistance, shock resistance, weather and chemical resistance

- UL94 V-0 flame retardant, meets RoHS environmental protection requirements

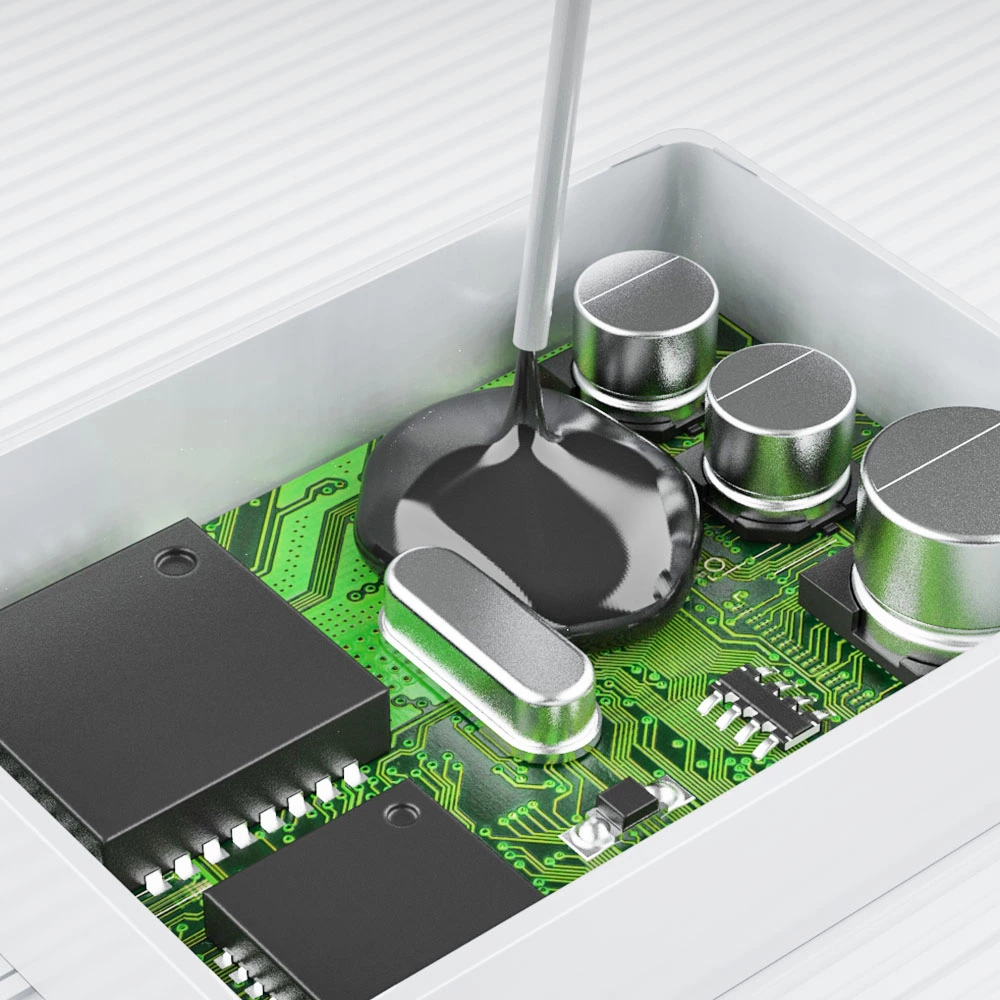

Thermally Conductive Potting Adhesive

Thermally conductive potting adhesive is a two-component polyurethane potting material with excellent electrical performance. It will not corrode components when used in electrical components, and has good adhesion to metals such as steel, aluminum, copper, tin, and materials such as rubber, plastic, PET, PVC, and PC.

It is used in LED driver power supplies to fix wires and circuit boards, so that electronic components and circuit boards are not affected by vibration, corrosion, moisture, dust, etc., further improving the service life of the driver power supply.

Features and Advantages

- Thermal conductivity of Fehonda thermally conductive potting adhesive: 0.6-1W/mk

- Low viscosity, easy to operate, temperature range: -60℃~135℃

- Excellent reliability such as aging resistance, acid and alkali resistance, corrosion resistance

- Excellent adhesion to metals, plastics, PET, PVC, PC and other materials

- Extremely small internal stress, little damage to devices, protect electronic components

- UL94 V-0 flame retardant, meets RoHS environmental protection requirements

The application of thermal conductive materials between LED lamp beads and radiators can not only effectively improve heat conduction efficiency and prevent LED overheating, but also help extend the service life of LED and maintain their good optical performance.

If you have more questions or need further information about the application of thermal pad, thermal grease, thermal conductive silicone and thermal conductive potting glue, please contact the Fehonda team for detailed information.