Composition of Thermal Conductive Silicone Grease

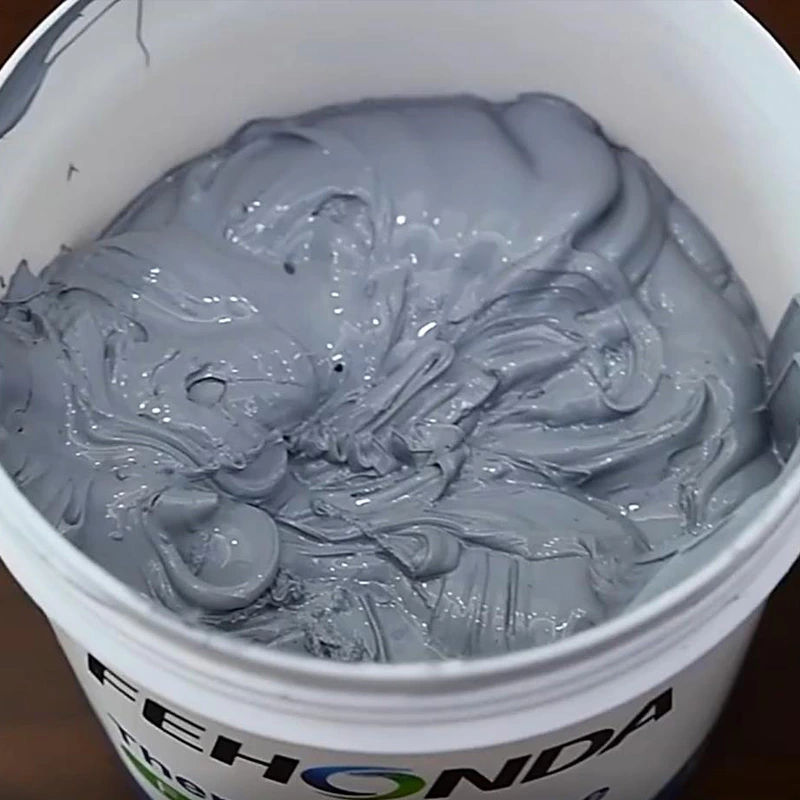

Thermal conductive silicone grease typically consists of three main components:

-

Silicone Oil Base: The silicone oil base provides the grease with its viscous nature, enabling it to spread easily and fill gaps effectively. It also provides good resistance to high temperatures and chemicals.

-

Thermally Conductive Particles: The thermally conductive particles, such as aluminum oxide or zinc oxide, are dispersed in the silicone oil base. These particles facilitate heat transfer by filling small gaps and voids between two surfaces, reducing thermal resistance and enhancing thermal conductivity.

-

Additives: Some thermal conductive silicone greases may contain additives, such as thickeners or anti-oxidants, to improve their performance or durability.

The exact composition of thermal conductive silicone grease may vary depending on the manufacturer and application requirements.

Properties of Thermal Conductive Silicone Grease

Thermal conductive silicone grease possesses several properties that make it ideal for heat dissipation applications:

-

High Thermal Conductivity: The thermally conductive particles in the grease facilitate heat transfer between two surfaces, enhancing thermal conductivity and reducing thermal resistance.

-

Gap Filling Capability: The grease can fill small gaps and voids between two surfaces, which improves thermal conductivity and reduces thermal resistance.

-

Temperature Resistance: Thermal conductive silicone grease can withstand high temperatures without losing its effectiveness. Some greases can operate up to 200°C or higher.

-

Electrical Insulation Properties: Some thermal conductive silicone greases have good electrical insulation properties, making them suitable for electronic applications where electrical insulation is required.

-

Chemical Resistance: Thermal conductive silicone grease has good resistance to chemicals, which helps to prevent corrosion or damage to the surfaces it comes into contact with.

-

Easy Application: Thermal conductive silicone grease is easy to apply, either manually or through automated dispensing systems.

Advantages of Thermal Conductive Silicone Grease

Thermal conductive silicone grease has several advantages over other TIMs, such as thermal pads or adhesives:

-

High Thermal Conductivity: Thermal conductive silicone grease possesses high thermal conductivity, enabling it to facilitate effective heat transfer, even in tight spaces.

-

Gap Filling Capability: The grease can fill small gaps and voids effectively, improving thermal conductivity and reducing thermal resistance.

-

Easy Application: Thermal conductive silicone grease is easy to apply manually or through automated dispensing systems, reducing labor costs and improving production efficiency.

-

Temperature Resistance: Thermal conductive silicone grease can withstand high temperatures without losing its effectiveness, ensuring stable performance over a wide temperature range.

-

Electrical Insulation Properties: Some thermal conductive silicone greases have excellent electrical insulation properties, making them suitable for electronic applications requiring electrical insulation.

Disadvantages of Thermal Conductive Silicone Grease

Thermal conductive silicone grease has a few disadvantages that should be considered:

-

Aging and Deterioration: Thermal conductive silicone grease can deteriorate over time, resulting in reduced thermal conductivity and effectiveness. Regular maintenance and replacement are necessary to ensure optimal performance.

-

Limited Thermal Conductivity: While thermal conductive silicone grease possesses high thermal conductivity, it may not be as effective as other TIMs, such as metallic TIMs, which have higher thermal conductivity.

-

Viscosity Impact: Viscosity levels can affect heat dissipation efficiency, and different applications may require different viscosity levels.

-

Curing Time: Some thermal conductive silicone greases require curing time for optimal performance, which can slow down production cycles.

Applications of Thermal Conductive Silicone Grease

Thermal conductive silicone grease is widely used in various applications, including:

-

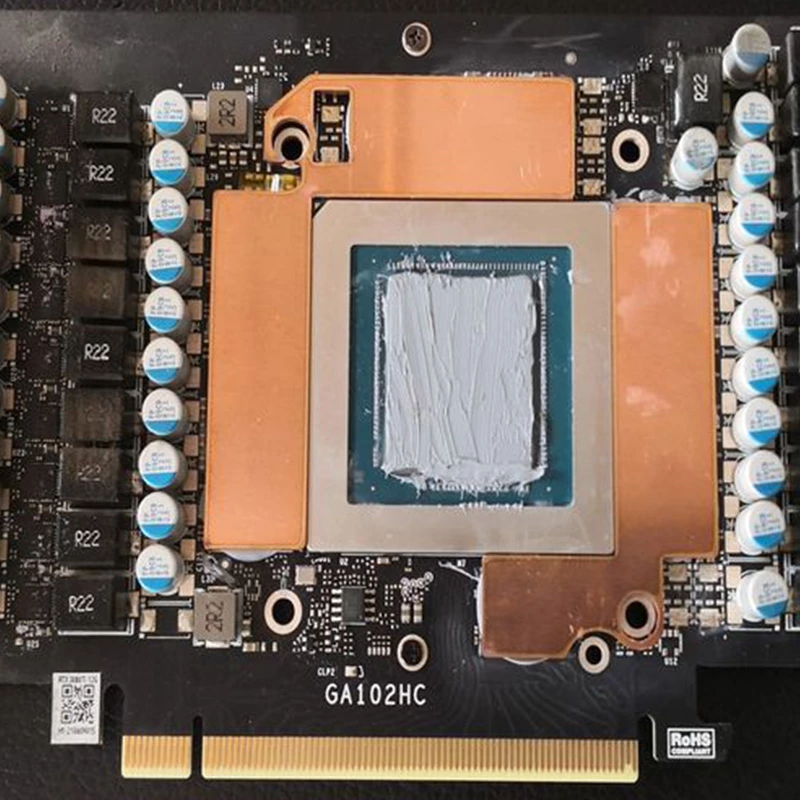

Electronic Devices: Thermal conductive silicone grease is commonly used in electronic devices, such as computers, laptops, smartphones, and tablets, to facilitate heat dissipation and prevent overheating.

-

Automotive Industry: The automotive industry uses thermal conductive silicone grease in various applications, such as engine control units (ECUs), power electronics, and LED lighting systems, to improve heat dissipation and reduce thermal resistance.

-

Industrial Equipment: Industrial equipment, such as power supplies, motor controllers, and inverters, use thermal conductive silicone grease to enhance heat dissipation and improve thermal management.

-

Medical Equipment: Medical equipment, such as ultrasound machines and MRI scanners, use thermal conductive silicone grease to facilitate heat dissipation and improve performance.

-

Consumer Electronics: Consumer electronics, such as smartwatches, fitness trackers, and gaming consoles, use thermal conductive silicone grease to prevent overheating and improve performance.

Usage Guidelines for Thermal Conductive Silicone Grease

To ensure optimal performance of thermal conductive silicone grease, follow these usage guidelines:

-

Surface Preparation: Clean the surface to be coated thoroughly to remove any dust, debris, or contaminants that may impede heat transfer.

-

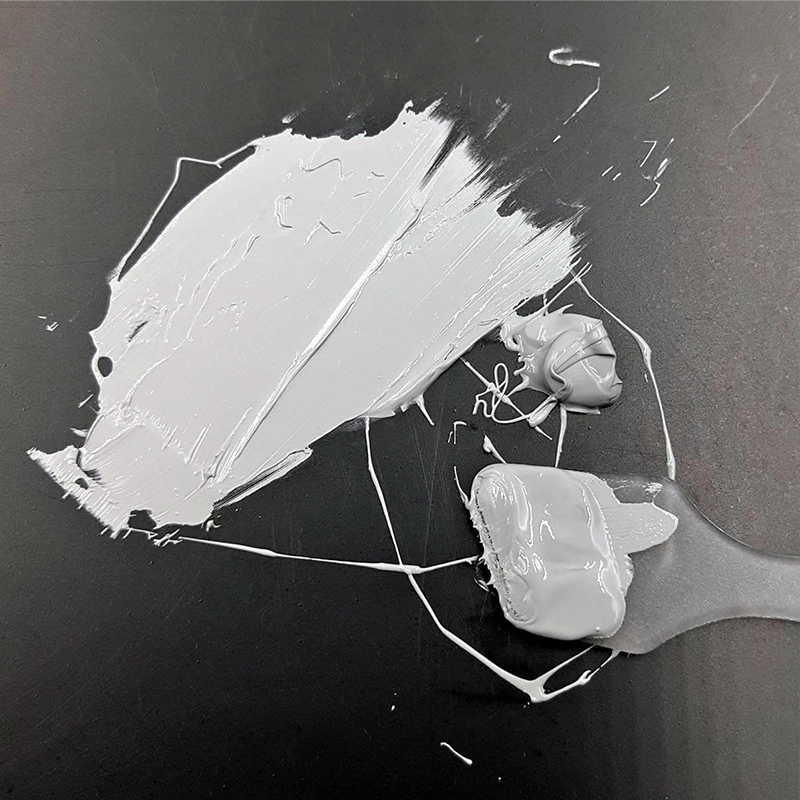

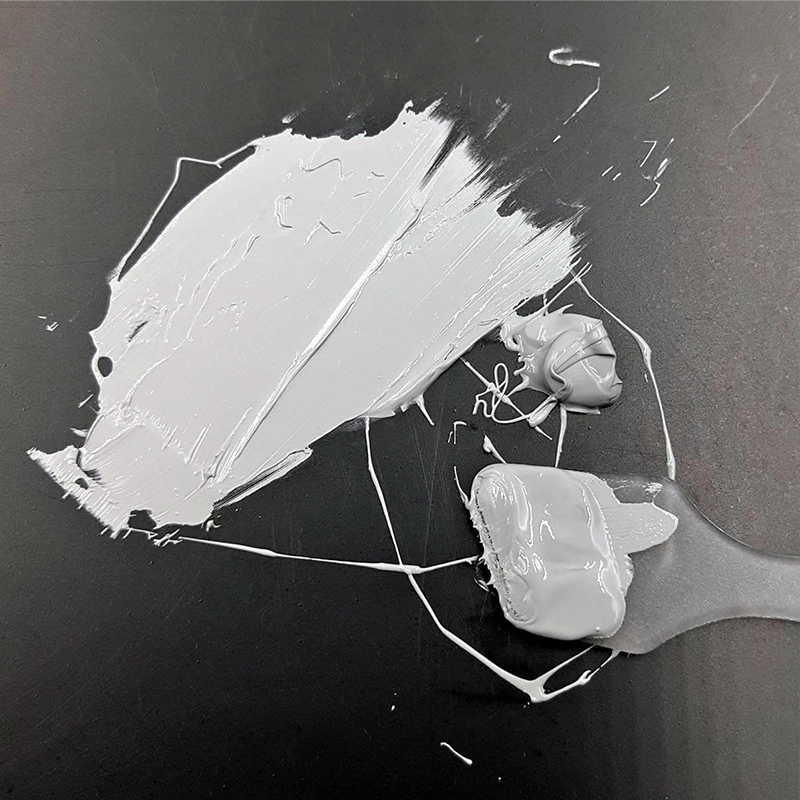

Even Application: Apply the thermal conductive silicone grease evenly on the surface to be coated, ensuring that it fills any small gaps and voids effectively.

-

Appropriate Quantity: Apply the appropriate quantity of thermal conductive silicone grease as per manufacturer recommendations to avoid over- or under-application, which can impact heat dissipation effectiveness.

-

Curing Time: Some thermal conductive silicone greases require curing time for optimal performance. Follow the manufacturer's instructions for curing time and methods.

-

Maintenance and Replacement: Regularly inspect the thermal conductive silicone grease for signs of deterioration, aging, or cracking. If necessary, remove the old grease and reapply a fresh layer to maintain optimal heat dissipation.

Conclusion

Thermal conductive silicone grease is a reliable and effective thermal interface material that has a wide range of applications in electronics, automotive, industrial, medical, and consumer electronics industries. Its high thermal conductivity, gap-filling capability, temperature resistance, electrical insulation properties, and ease of application make it an ideal choice for heat dissipation solutions. However, it is essential to follow the manufacturer's usage guidelines and perform regular maintenance to ensure optimal performance.