Thermal conductive materials play a crucial role in the electronics industry, with thermal conductive silicone grease and thermal conductive gel being two common types. Both of these thermal interface materials are in a paste-like form, but how do you choose between thermal conductive silicone grease and thermal conductive gel? Let's delve into the differences between these two materials.

Explained in a Single Article,The Difference Between Thermal Grease and Thermal Gel

Thermal grease

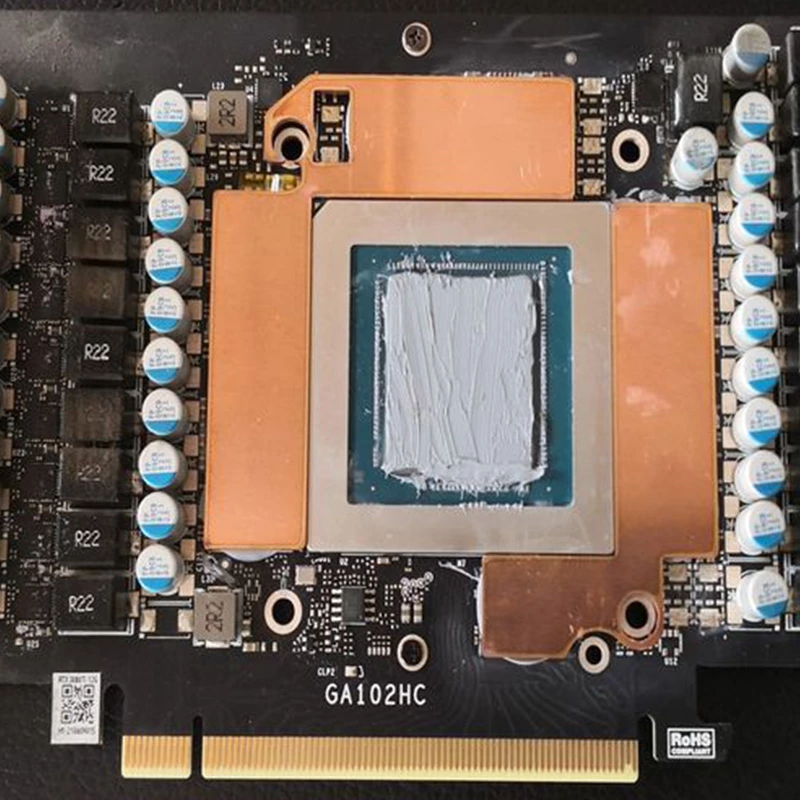

Thermal conductive silicone grease, also known as thermal paste or thermal compound, is composed of 'silicone oil + filler.' The filler consists of finely ground powders such as zinc oxide, aluminum oxide, boron nitride, silicon carbide, aluminum powder, and others. The silicone oil ensures a certain level of fluidity, while the filler fills in the tiny gaps between the CPU and heatsink, ensuring thermal conductivity. It has a wide range of applications and is suitable for almost any heat dissipation requirement.

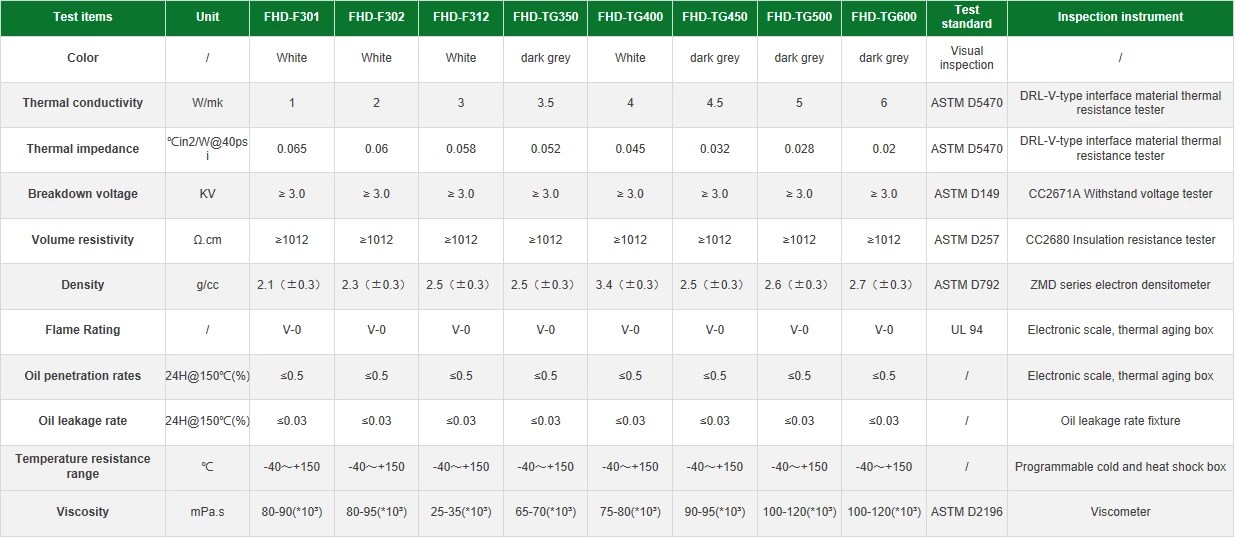

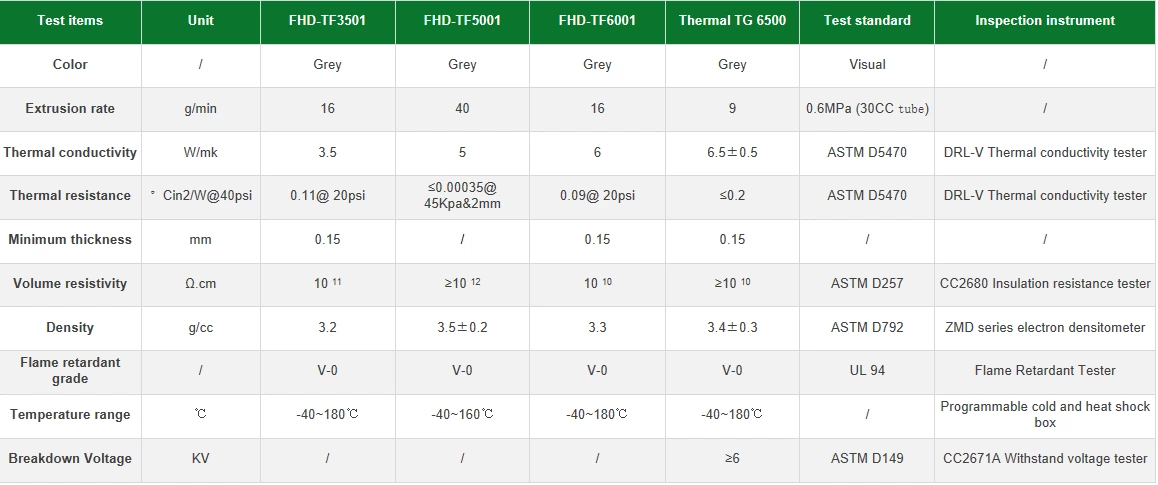

Performance Parameters

Application Scenarios

Applied for thermal conduction between ICs, CPUs, MOSFETs, IGBTs, and heatsinks, such as PCs, LEDs, DVDs, power supplies, communication products, network terminals, consumer electronics, power devices, storage devices, LED lighting fixtures, etc

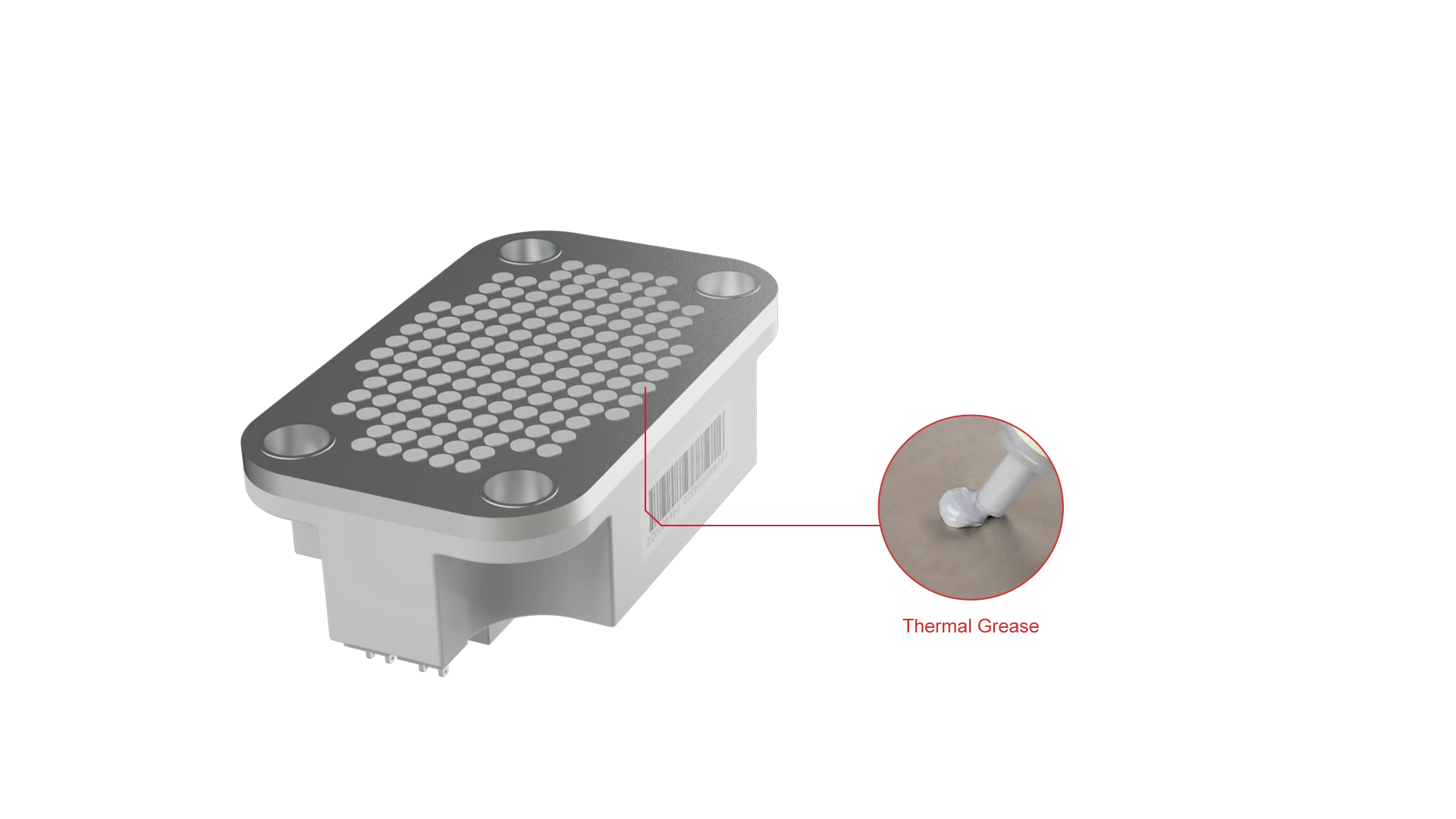

Thermal gel

Thermal conductive gel is a gel-like silicone-based thermal conductive material, available in single-component and two-component combinations. It is made by stirring and mixing silicone resin, cross-linking agent and thermal conductive filler. It is suitable for microscopically uneven contact surfaces. The colloid is formed according to the shape of the structure, with strong surface conformability and sufficient gap filling. The product has excellent insulation voltage resistance and high and low temperature resistance, high reliability in long-term use, and can be automatically dispensed to achieve automated operations.

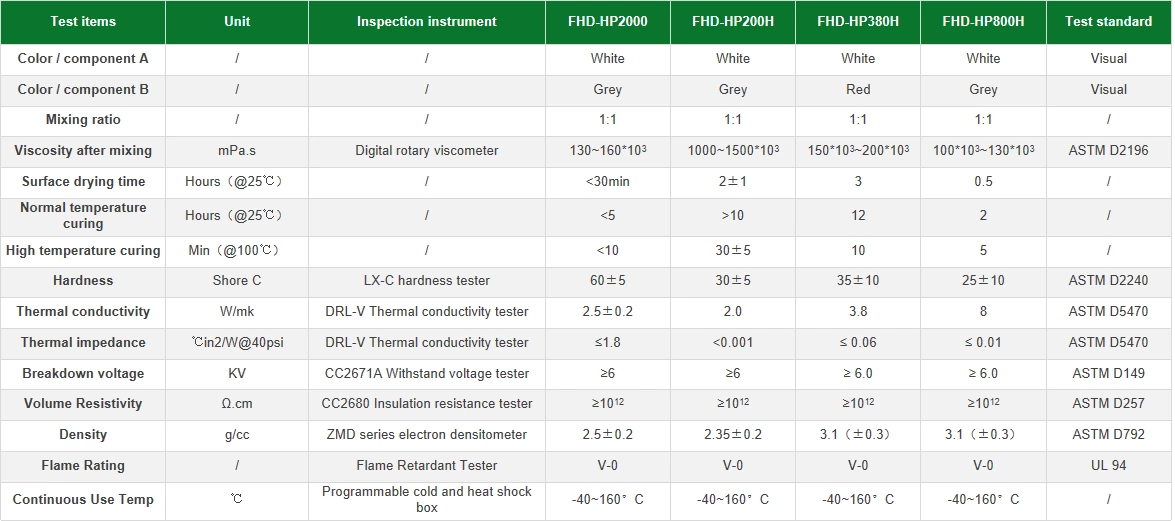

Performance Parameters

Single-component gels

Two-component gels

Application Scenarios

It is used in the contact surface between heating elements (power tubes, thyristors, electric heating piles, etc.) and heat dissipation facilities (heat sinks, shells) in various electronic products and electrical equipment. It plays an intermediate role in transmitting heat and moisture, and is dust-proof and dust-proof. Corrosion, shockproof and other properties.

Difference between thermal grease and thermal gel

Thermal conductive gel is easier to operate than thermal conductive silicone grease. Silicone grease is generally used by screen or steel plate printing, or direct brushing, and due to its certain fluidity, it generally cannot be used in situations with a thickness of more than 0.2mm. Thermal conductive gel has certain adhesion, can be compressed into various shapes, and does not have the problem of oiling and drying out, so it has certain advantages in reliability.

Thermal conductive gel has certain advantages in continuous operation. The commonly used continuous use method is a dispensing machine, which can achieve fixed-point quantitative control, save labor and improve production efficiency.

There are many differences between thermal grease and thermal gel, such as application scenarios, lifespan, insulation performance, etc. Therefore, thermal conductive gel is not thermal conductive silicone grease. Both have their own uses. Users can choose the appropriate thermal conductive material according to their own product characteristics and product structure requirements.

If you want to know how to apply thermal conductive materials to your products, please contact Fehonda team for detailed information.