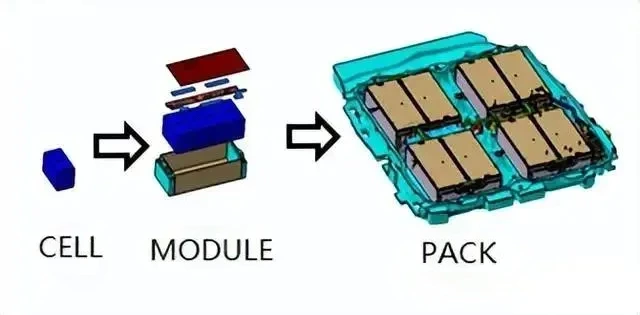

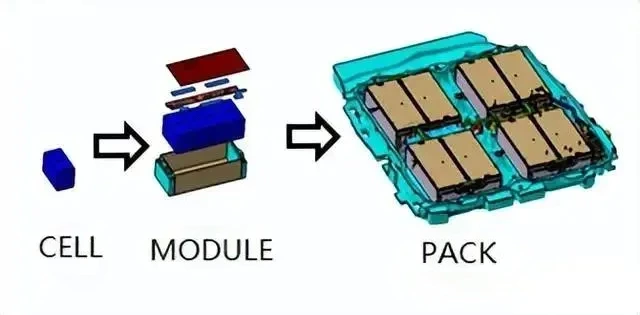

Cells >>> Battery PACK

* To assemble a battery module, a certain number of cells are connected in series and parallel.

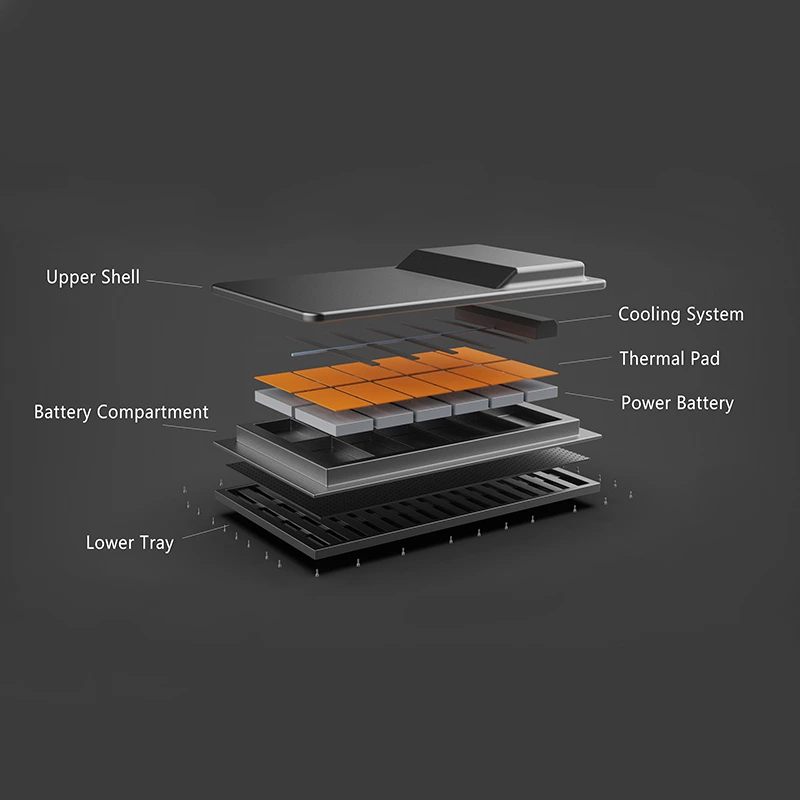

* A complete battery pack, also known as a battery PACK, consists of a battery module, a thermal management system, a battery management system (BMS), and some structural components.

Battery Module

The battery PACK is responsible for storing and releasing energy to provide power for the car.

Mechanism System

The mechanism system mainly consists of the battery PACK cover, tray, various metal brackets, end plates and bolts. It can be regarded as the skeleton of the battery PACK, which plays the roles of support, resistance to mechanical impact, mechanical vibration and environmental protection (waterproof and dustproof).

Electrical System

The electrical system mainly consists of high-voltage jumper or high-voltage wiring harness, low-voltage wiring harness and relays. The high-voltage harness can be regarded as the artery and blood vessel of the battery PACK and it can continuously deliver the power from the heart of the power battery system to each required component. The low-voltage harness can be regarded as the neural network of the battery PACK, which transmits detection and control signals in real time.

Thermal Management System

There are four main types of thermal management systems: air-cooled, water-cooled, liquid-cooled, and phase change materials. Taking the water-cooled system as an example, the thermal management system mainly consists of cooling plate, cooling water pipe, heat-insulating pad and heat-conducting pad. The thermal management system can be regarded as the air conditioner of the battery pack.

BMS Battery Management System

The battery management system, which can be regarded as the brain of the battery, is mainly composed of CMU and BMU.

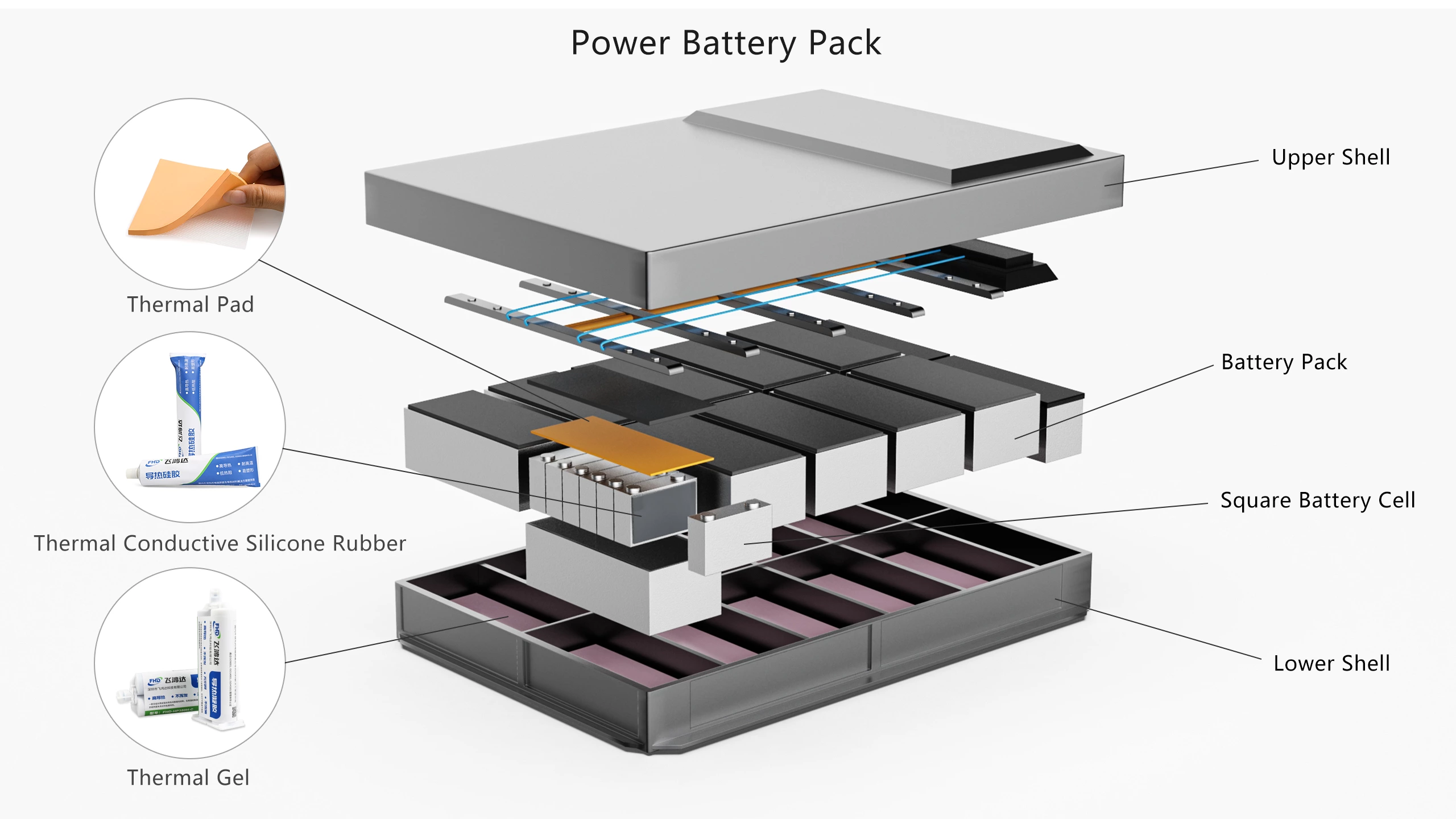

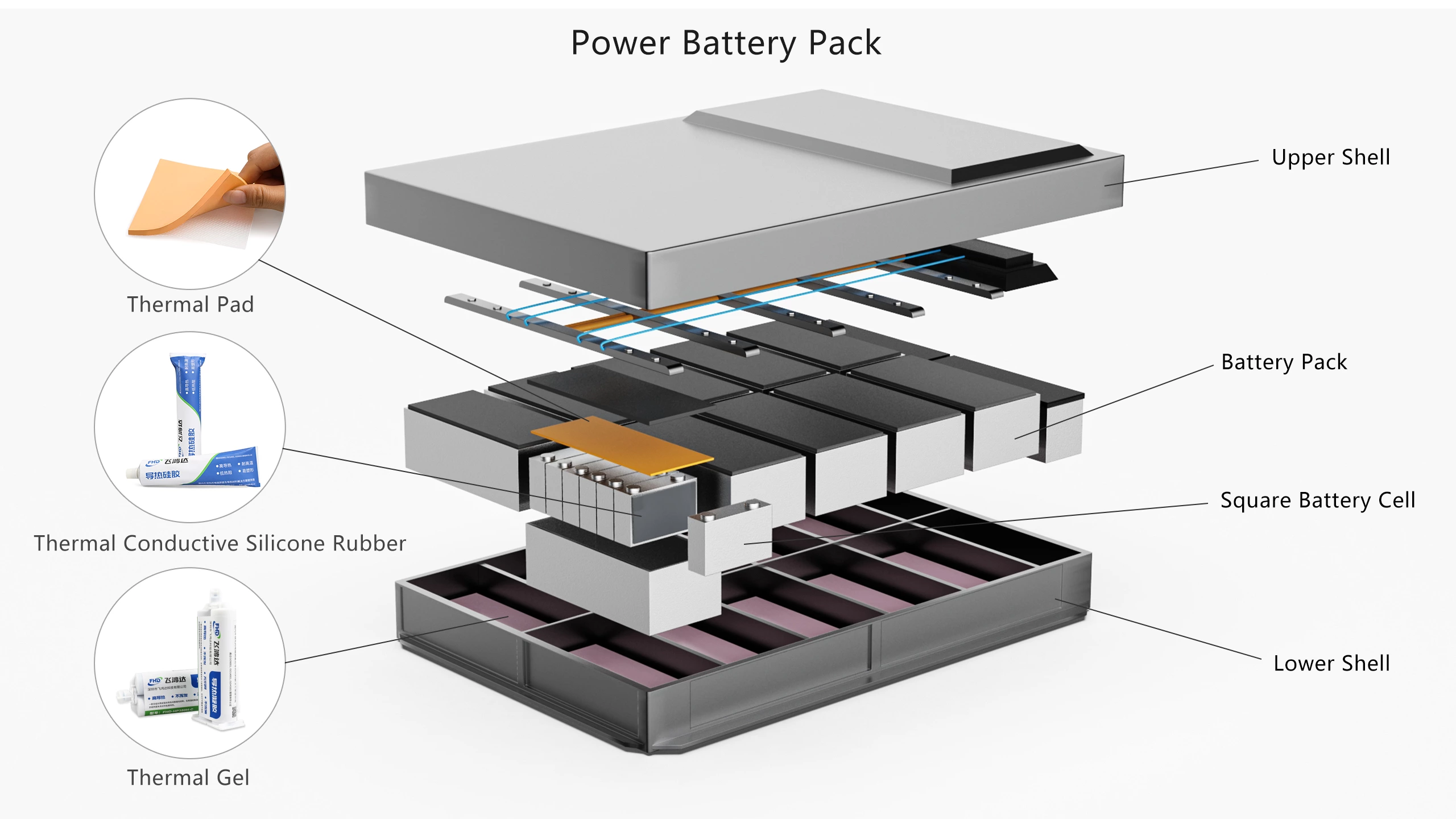

Battery PACK-Thermal Conductive Material Solutions

The application of thermally conductive materials in the field of new energy vehicles is a crucial technological advancement that plays a key role in improving the performance, safety and efficiency of vehicles. With the increasing global awareness of sustainable energy and environmental protection, the demand for new energy vehicles is growing rapidly. Against this background, the application of thermally conductive materials has become an important aspect of enhancing the performance of new energy vehicles.

Thermally conductive materials are a class of materials that can effectively transfer heat energy, and they play a role in several key areas in new energy vehicles. In battery PACK, thermally conductive materials can regulate the temperature of the battery to ensure that battery operates at the optimal operating temperature and prevent overheating. It extends battery life and increases energy density and charge/discharge efficiency. Therefore, it is crucial for battery safety.

Thermal Pad

Thermal Pad

Thermal conductivity: 2~3 W/mk

Hardness: 25~35 Shore00

Product features: ultra-soft, high resilience, tear-resistant.

Role: thermal conductivity, shock absorption and cushioning.

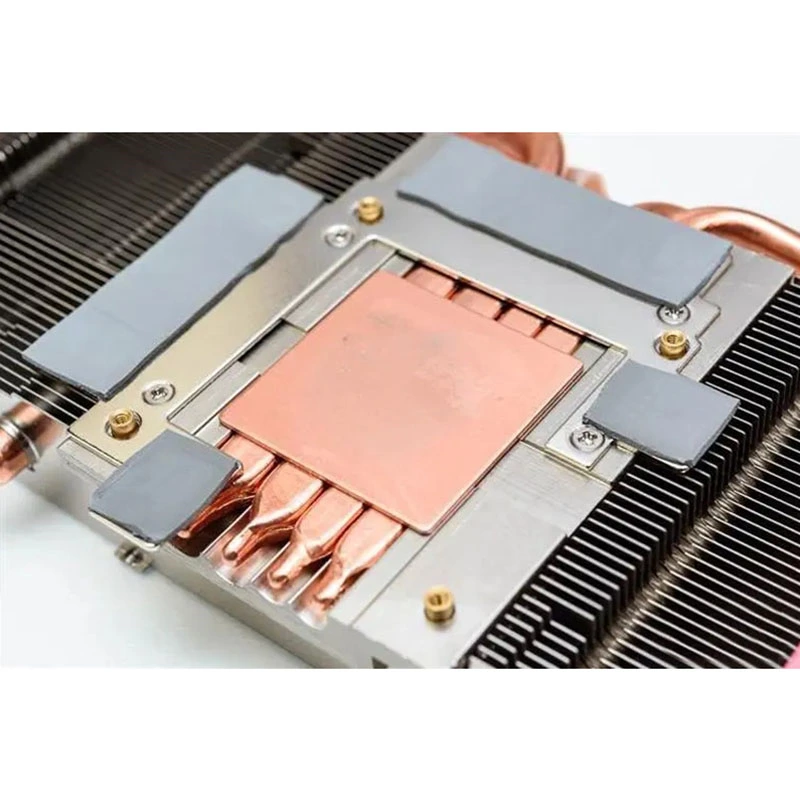

Thermal Gel

Thermal conductivity: 1~3.5 W/mk

Hardness: 40~75 Shore 00

Product features: utra-high compliance, Excellent wettability when used on low-stress interfaces.

Function: Used on the top and side walls of the shell, it can play a role in heat dissipation and fixed anti-vibration. It can also increase the thermal conductivity area of the heterogeneous parts and reduce the interface thermal resistance. In addition, it can be used automatically.

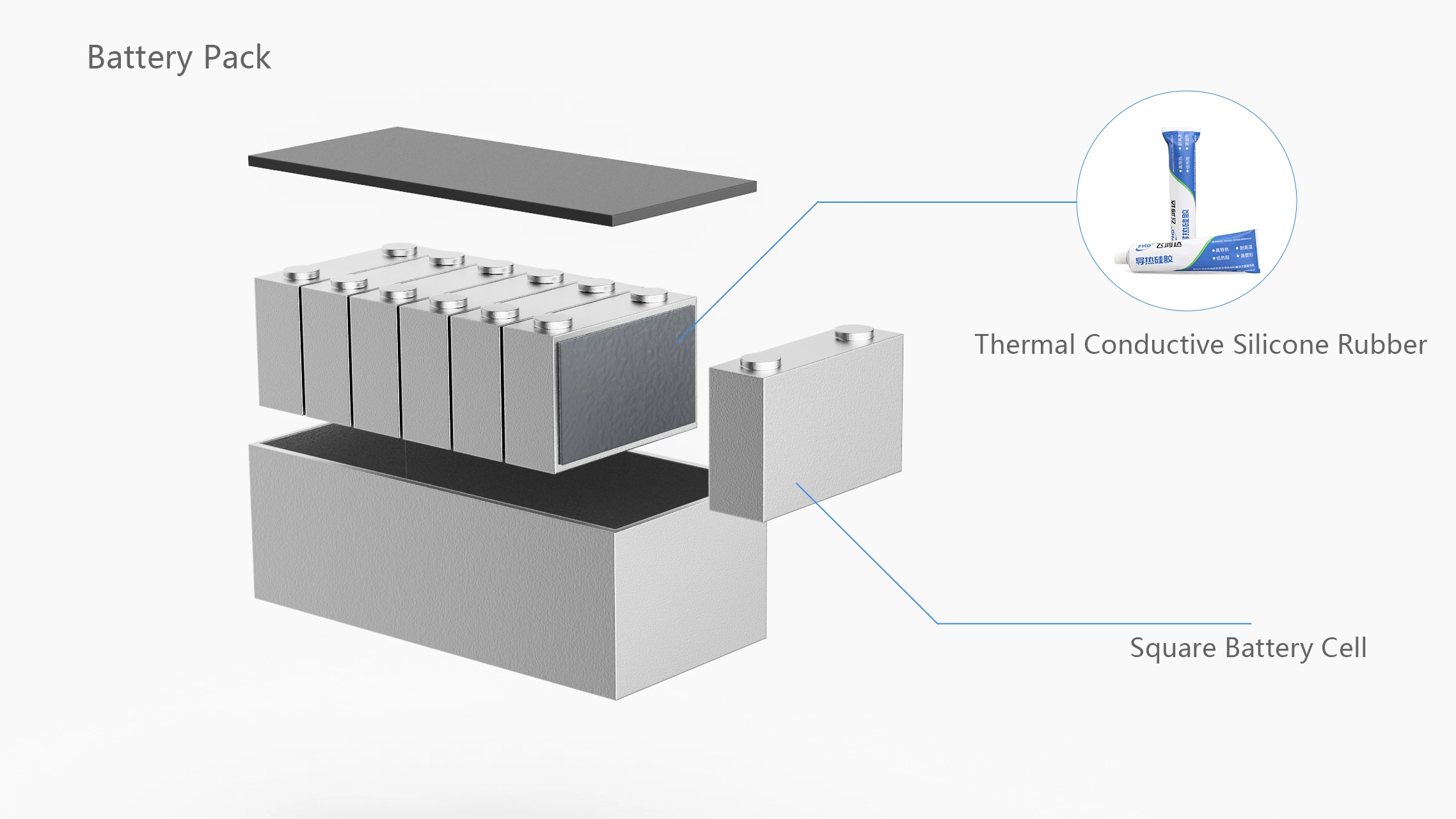

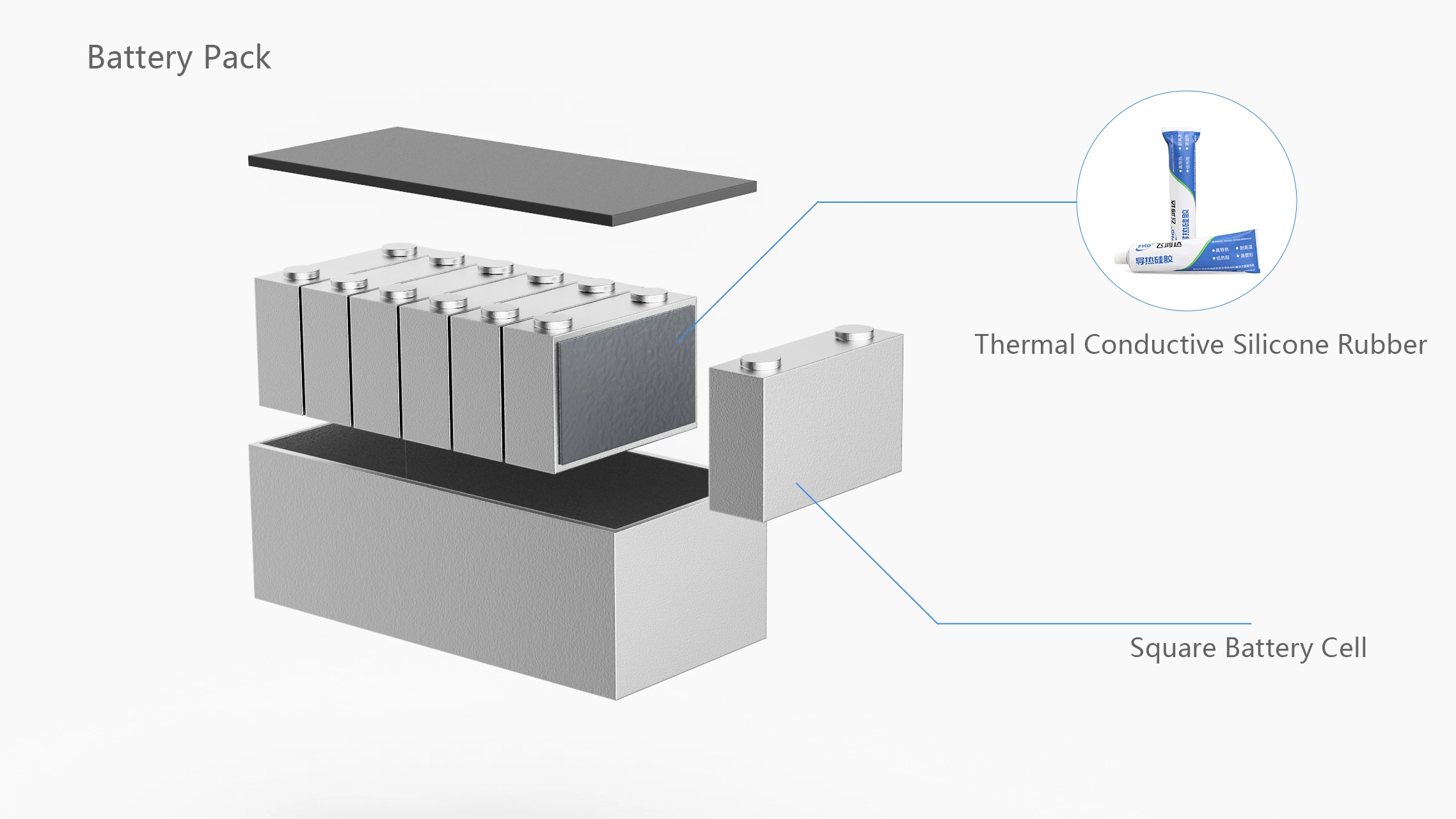

Thermal Conductive Silicone Rubber

Thermal conductivity: 1~2 W/mk

Product features: excellent resistance to hot and cold alternation, aging resistance, and high electrical insulation properties.

Function: When used between battery cells, it can play the role of heat conduction, insulation, bonding and sealing. The battery module is assembled by a certain number of battery cells in series and parallel.

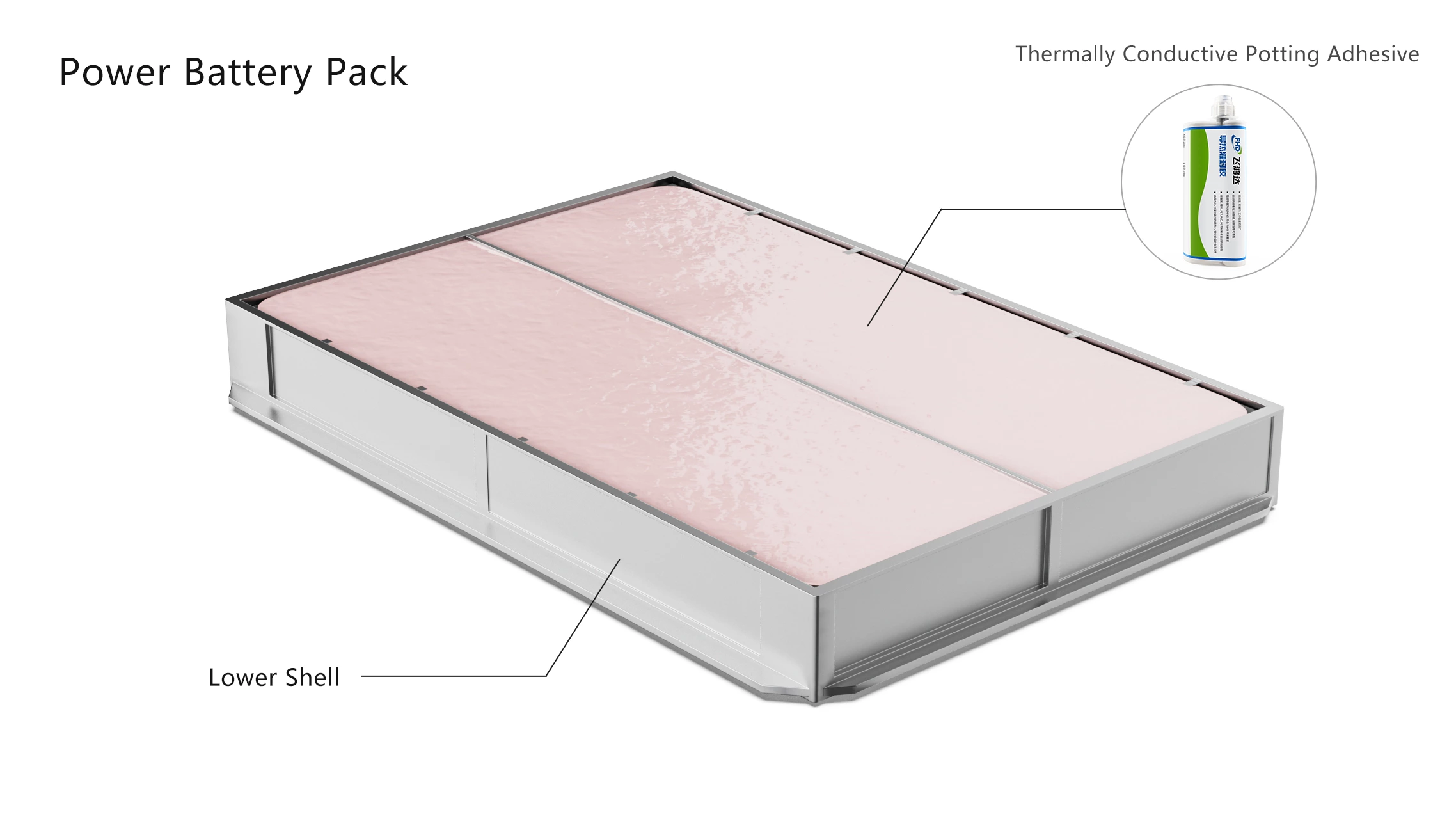

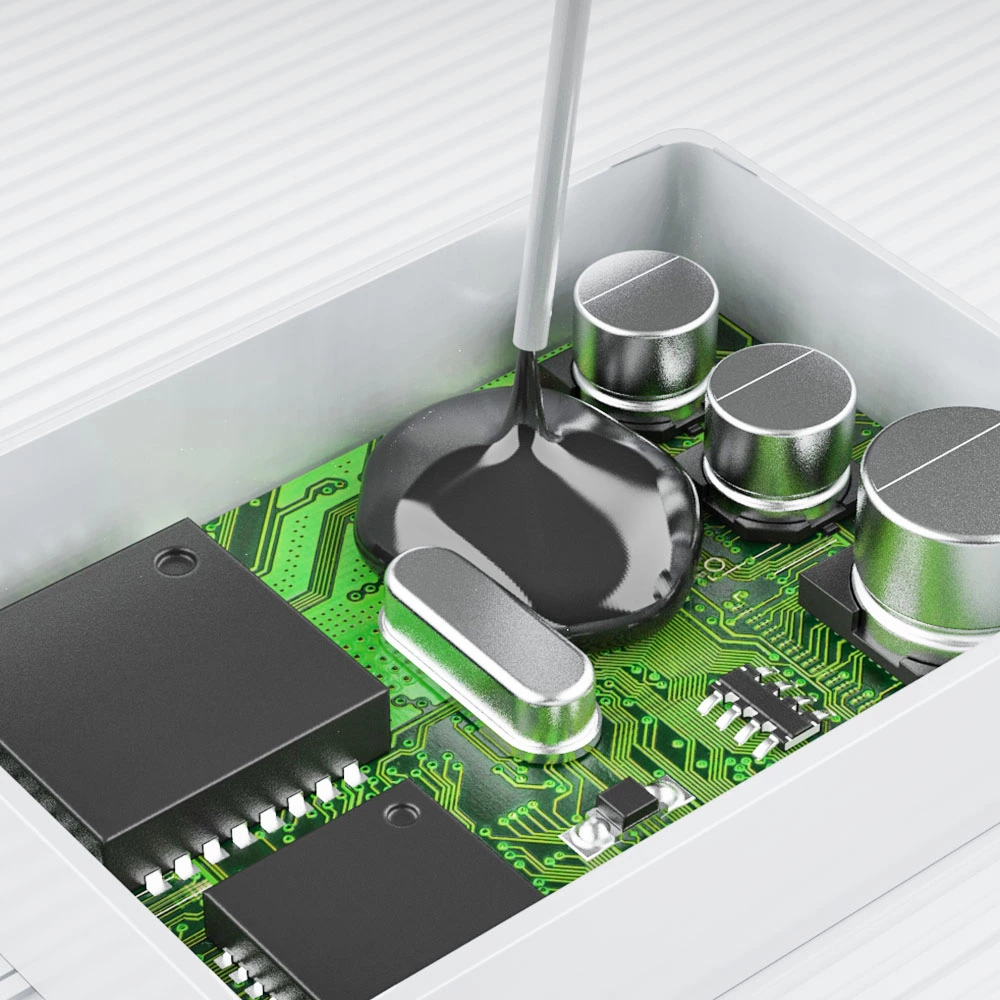

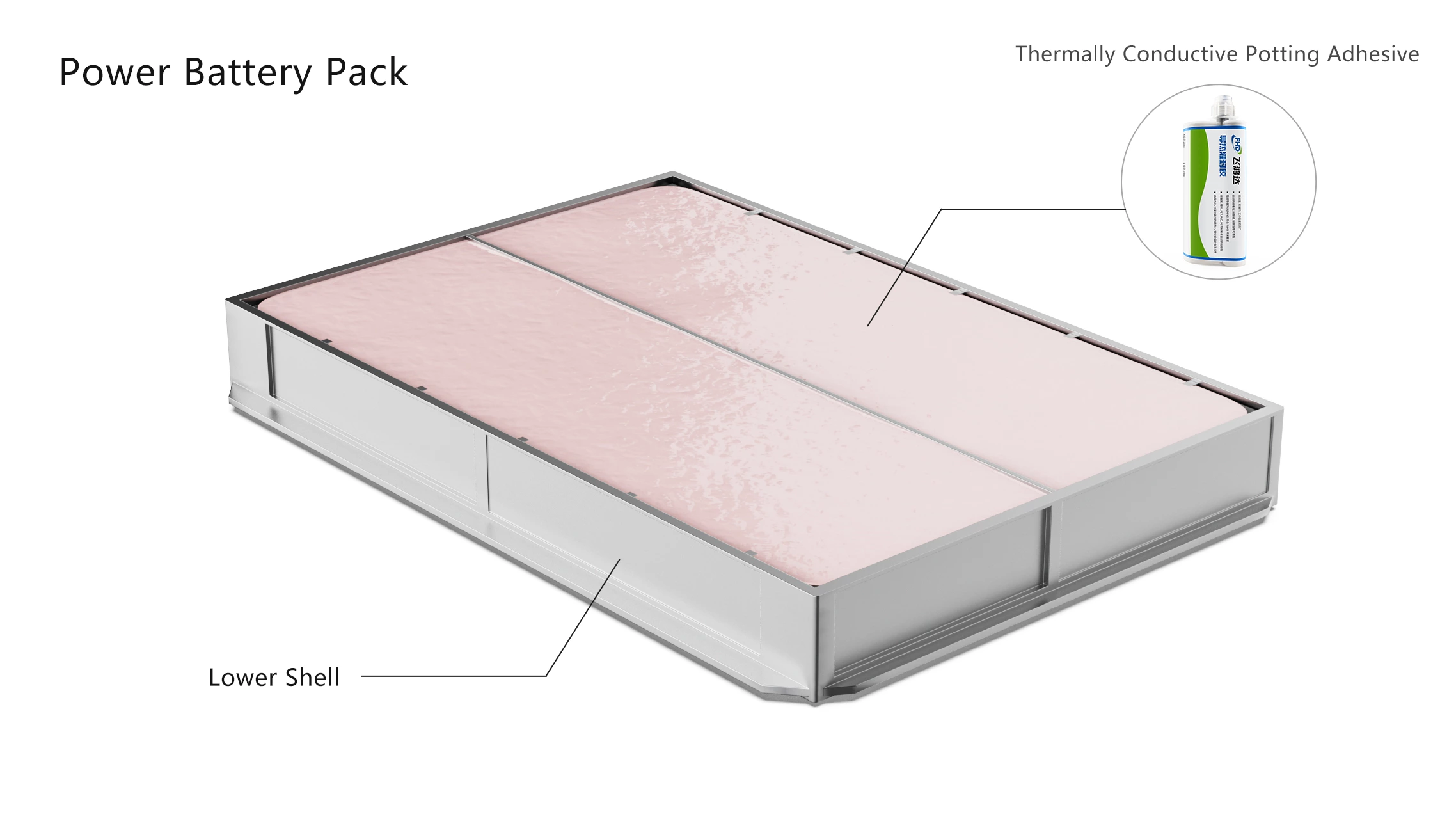

Thermally Conductive Potting Adhesive

Thermal conductivity: 0.6~2 W/mk

Product features: low density, high insulation strength, good fluidity, flame retardant.

Role: It is used between the power battery module and PACK liquid cooling plate, playing the role of heat conduction, bonding and sealing. It ensures that the internal devices of new energy vehicles are firmly sealed during operation, prevents the internal devices from collision damage, and at the same time plays the role of heat conduction and dissipation.

The application of thermally conductive materials in new energy vehicles is of great significance in improving the overall performance and safety of the vehicles. With the continuous expansion of the new energy vehicle market and technological innovation, it is expected that the demand for thermally conductive materials in this field will continue to increase. Thermally conductive materials will provide strong support for the development of new energy vehicles.

If you have more questions about the application of thermal pad, thermal gel, thermal conductive silicone rubber, Thermally Conductive Potting Adhesive or need further information, welcome to contact Fehonda team for detailed information.