What are thermal conductive materials?

Thermal conductive materials are a type of thermal interface materials (TIM) that are filled between the heat source and the heat sink. They are used to fill the tiny gaps and holes on the uneven surface generated during bonding or contact, reduce thermal resistance, and improve the heat dissipation performance of the device.

Here are some thermal conductive materials independently developed and produced by Fehonda: thermal pad, thermal gel, thermal grease, thermal conductive insulator, thermal conductive phase change material, thermal conductive silicone rubber, thermally conductive potting adhesive, etc.

Why are thermal conductive materials so important?

Thermal conductive materials are widely used. They are often used in the cooling system of electronic devices. During the machining and the production of electronic components, there will be certain gaps and gullies between chips, and there will be a lot of air between these gaps. However, air is a poor conductor, which will seriously affect the heat dissipation efficiency between chips, and sometimes also affect the effect of the heat sink. Therefore, thermal conductive materials are needed to fill these gaps.

The excellent thermal conductivity of thermal conductive materials ensures that devices can continue to operate efficiently.

Here is a detailed introduction about 7 types of Fehonda thermal conductive materials, including their characteristics and advantages.

Product Recommendation

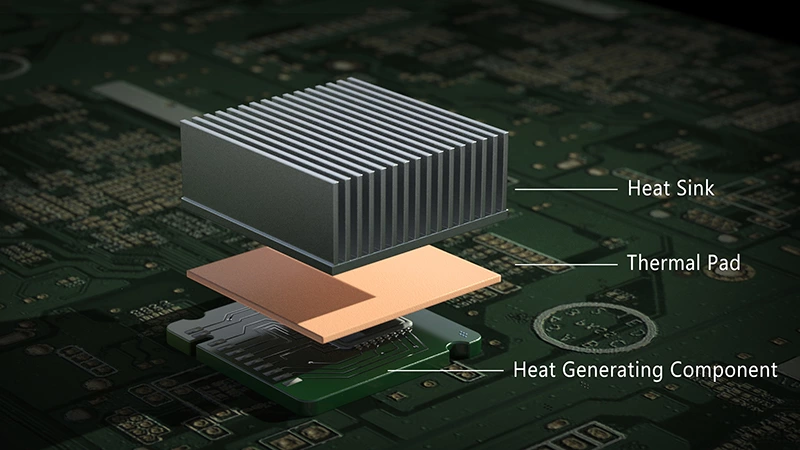

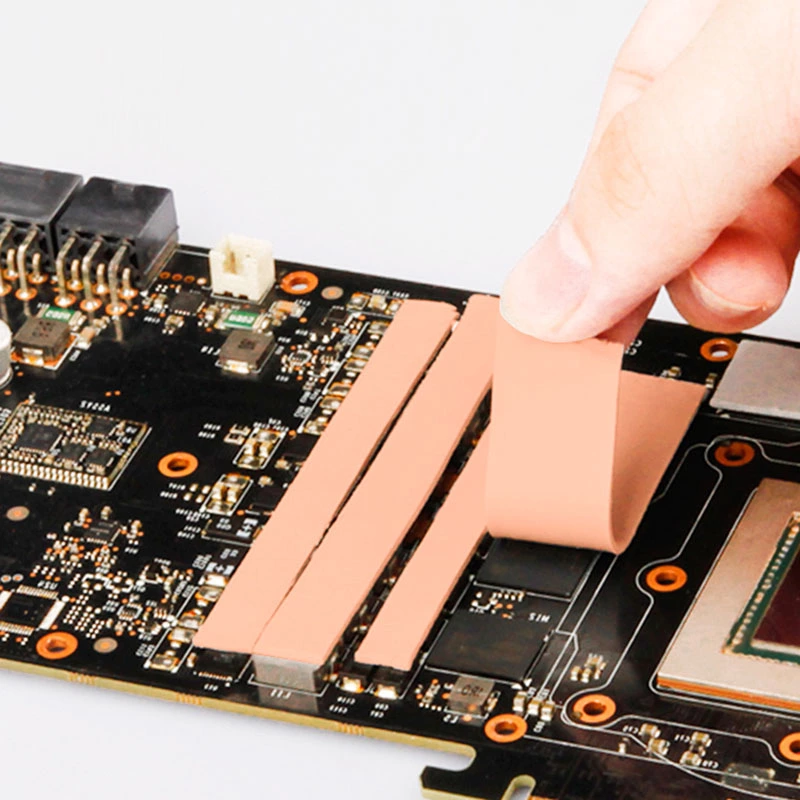

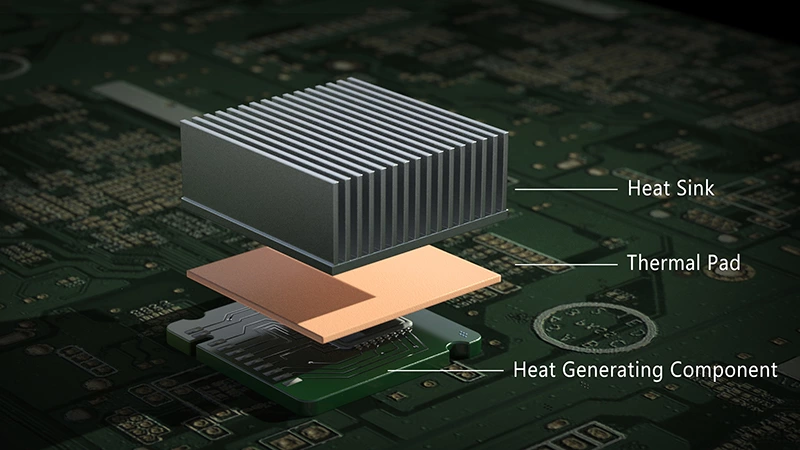

Thermal Pad

Thermal pad has many advantages, such as good insulation, compressibility, softness, and excellent thermal conductivity. The surface of thermal pad is sticky. It can be used to fill the gap between the heat source and the heat sink and squeeze out the air to achieve full contact, so that the heat conduction between the heating part and the heat dissipation part can be completed efficiently. At the same time, thermal pad can play the role of insulation and shock absorption, and it can also meet the design requirements of miniaturization and ultra-thinness. In general, thermal pad is an excellent thermal conductive filling material and it is widely used in various electronic components.

Thermal pad is widely used in communication equipment, network terminals, LED lighting, 3C electronics, new energy vehicles, high-power power supplies and other fields.

Features and Advantages

- Thermal conductivity of Fehonda thermal pad: 1.5-10.0W/mk

- Low thermal resistance, excellent thermal conductivity, good weather resistance

- Self-adhesive, good fit, easy to assemble

- Soft, good compressibility, high reliability in long-term use

- UL94 V-0 flame retardant, meets RoHS environmental protection requirements

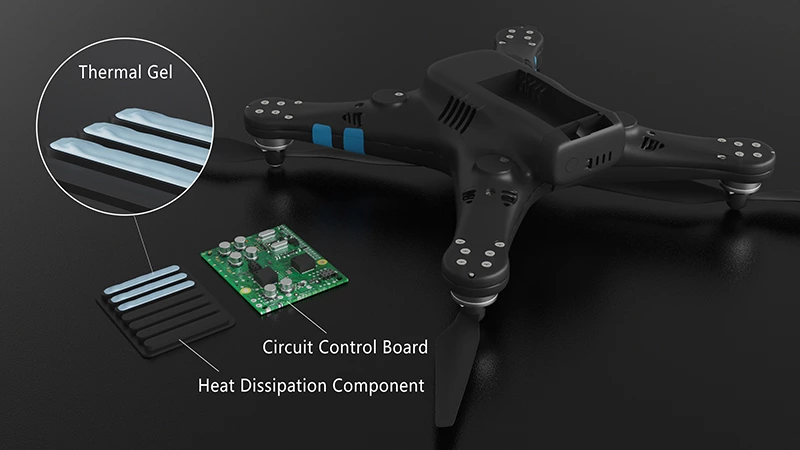

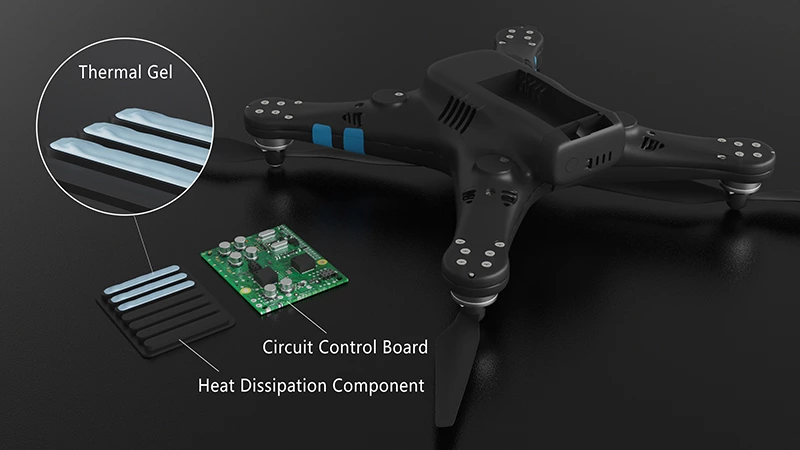

Thermal Gel

Thermal gel is a paste-like gap-filling thermal conductive material that can be cured at room temperature or high temperature. After curing, it appears as a flexible rubber elastomer. Thermal gel has the characteristics of excellent surface conformability and is suitable for contact surfaces with microscopic unevenness. The gel is formed with the shape of the structure and can be used to fully fill the gap. Since the gel has the characteristics of excellent insulation, pressure resistance, and high and low temperature resistance, it shows high reliability when used for a long time. In addition, it can also be used for automatic dispensing to achieve automated operations.

Thermal gel is used in many fields, such as power devices, network terminals, communication equipment, security equipment, consumer electronics, mobile terminals, and instruments.

Features and Advantages

- Thermal conductivity of Fehonda thermal gel: 2-8W/mK

- Excellent weather resistance, high and low temperature resistance, and insulation

- No sedimentation, no flow, it can be used to fill uneven gaps and can be used for automated dispensing

- UL94 V-0 flame retardant, meets RoHS environmental protection requirements

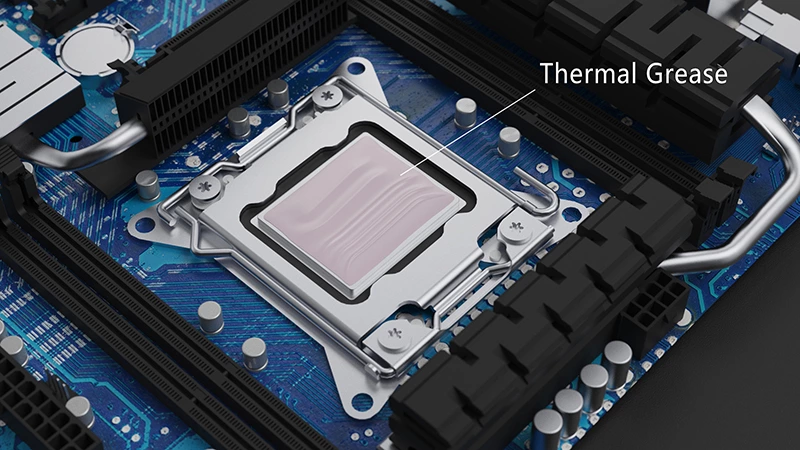

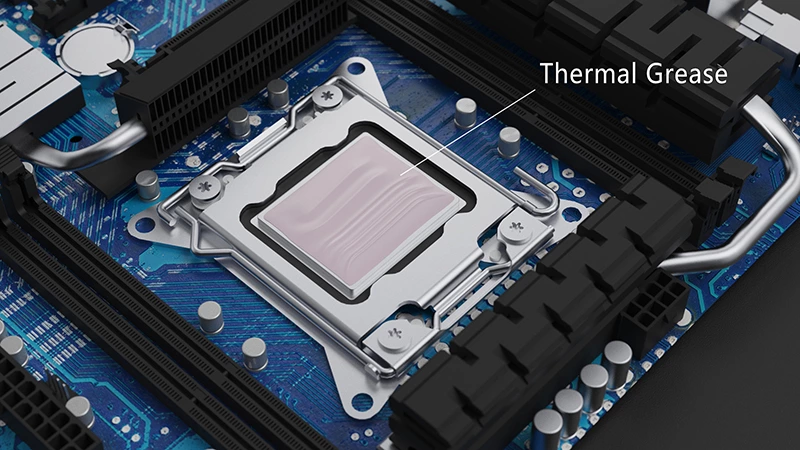

Thermal Grease

As a medium for transferring heat, thermal grease has many advantages, such as excellent thermal conductivity, good lubricity, electrical insulation, good resistance to high and low temperatures, low viscosity and good construction performance. In addition, it also has the characteristics of low usage thickness and low thermal resistance, which makes it suitable for scenarios with high heat generation and close fit. It can be used to quickly transfer heat from the device to achieve good temperature control, thereby extending the service life of electronic components and improving their reliability. It can be placed on the heating device by dispensing, printing, etc. Thermal grease is a excellent thermal conductive composite material suitable for smaller gaps or no gaps.

Thermal grease is used for heat conduction between IC, CPU, MOS, IGBT and heat sink and it is widely used in fields such as PC, LED, DVD, power supply, communication products, etc.

Features and Advantages

- Thermal conductivity of Fehonda thermal grease: 1-6W/mK

- Excellent thermal conductivity, high stability, excellent wetting performance

- Low thermal resistance, easy construction, and a very thin interface layer can be formed on the rough surface

- UL94 V-0 flame retardant, meets RoHS environmental requirements

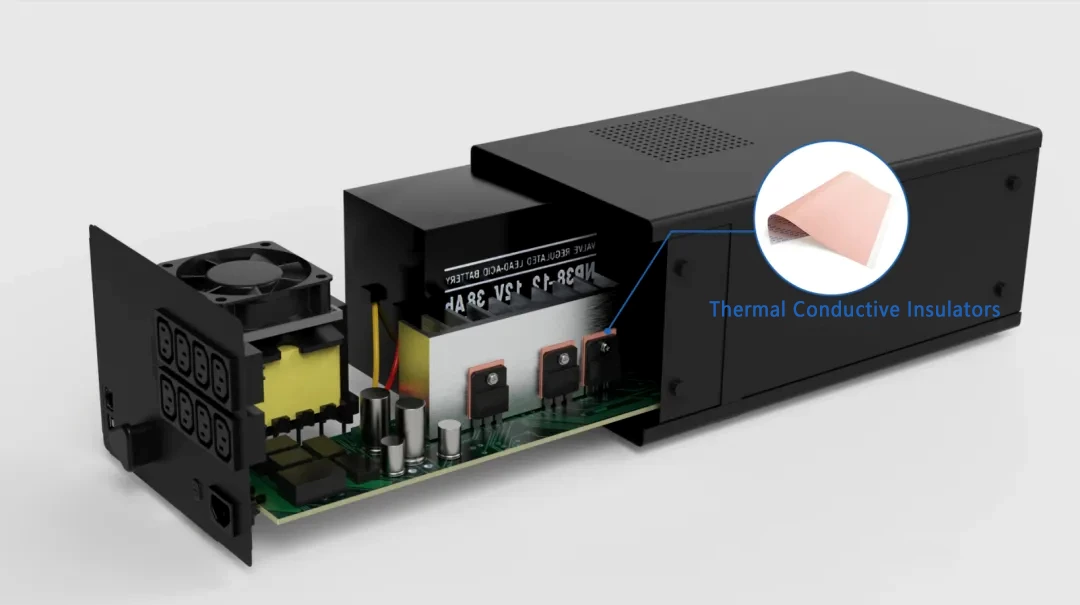

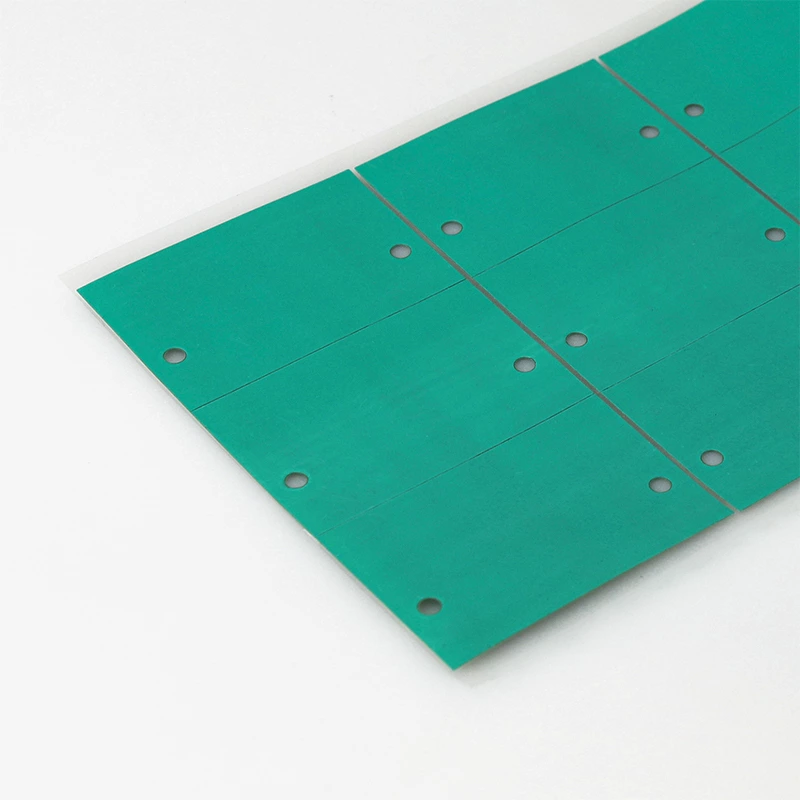

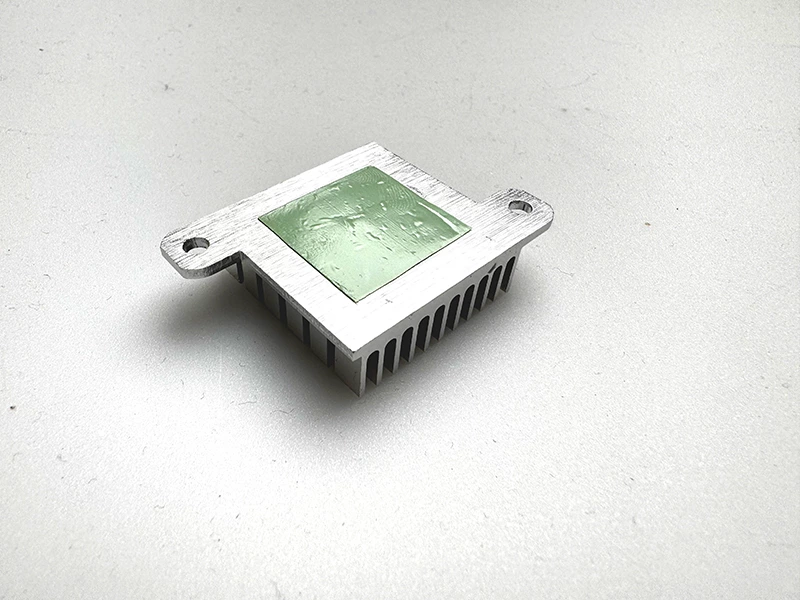

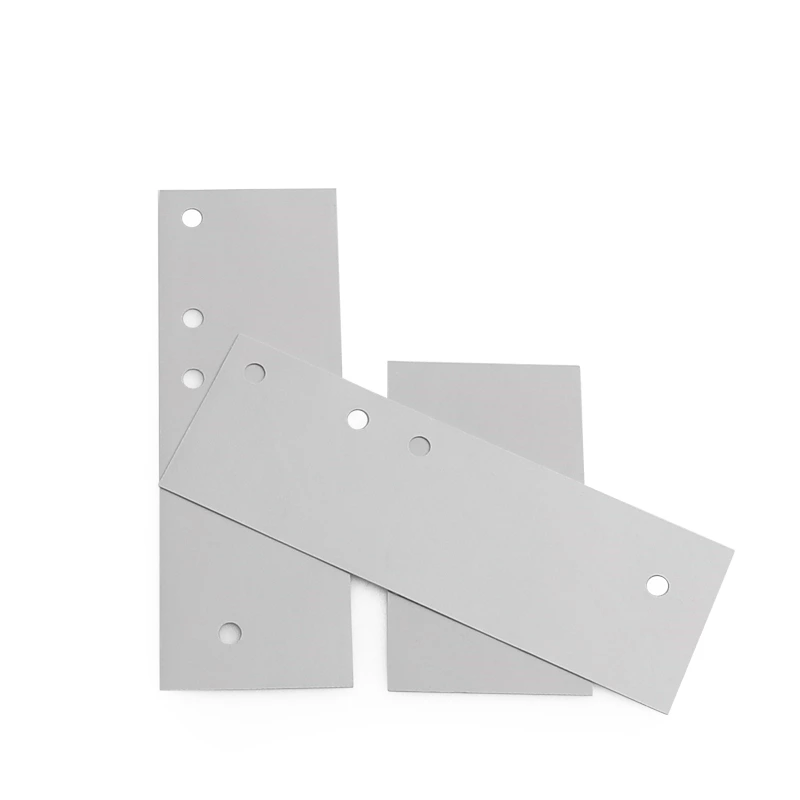

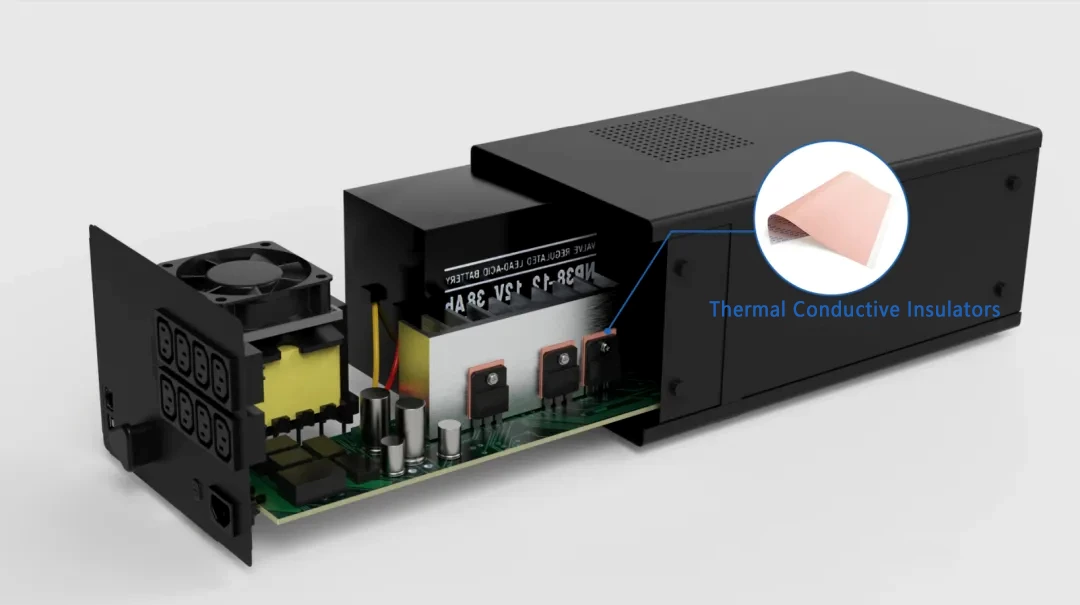

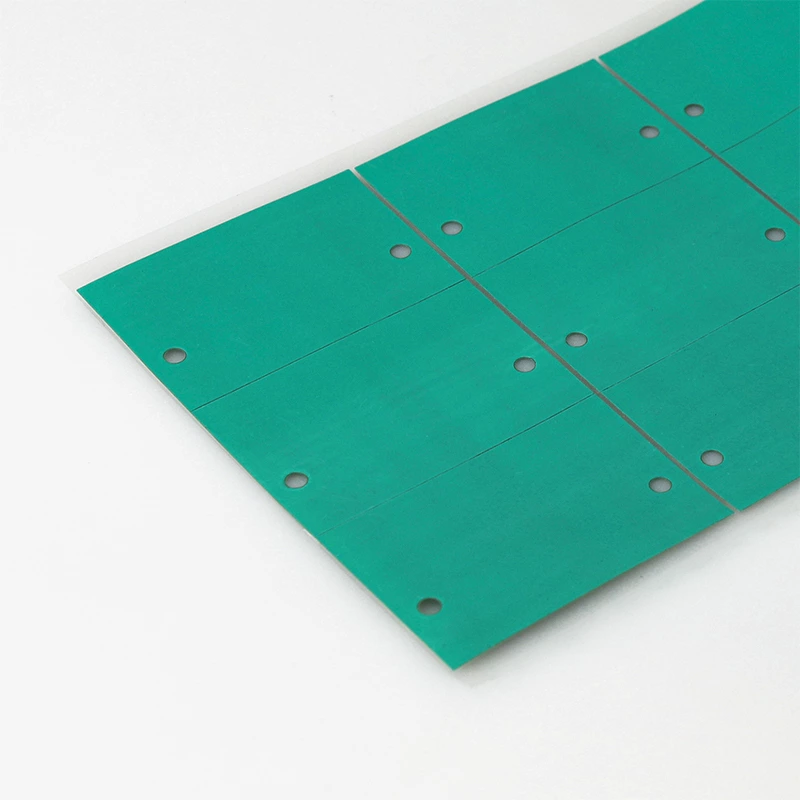

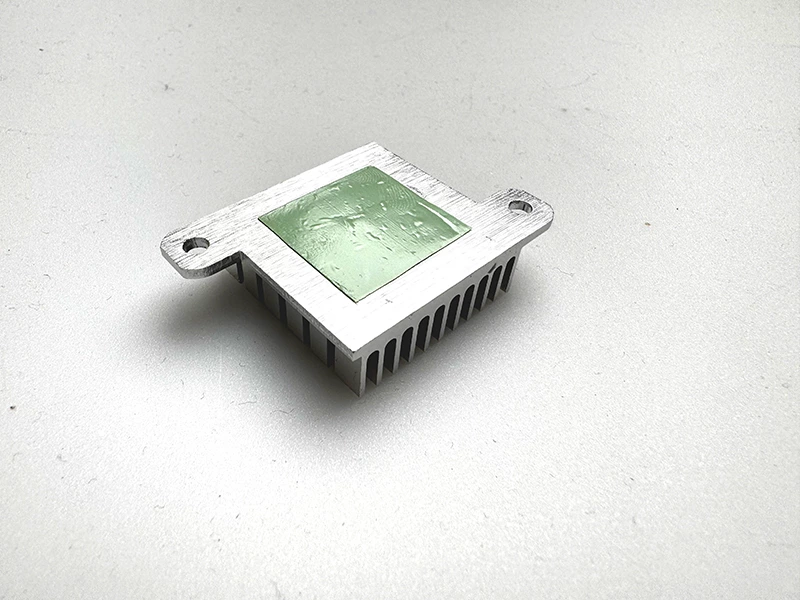

Thermal Conductive Insulator

Thermal conductive insulator is a product made of thermal conductive silicone rubber and glass fiber. The product can be used to effectively reduce the thermal resistance between electronic components and the heat sink and increase the heat transfer rate. It has the characteristics of electrical insulation and high dielectric strength, which enables it to resist high voltage and circuit short circuits caused by piercing of metal parts. The surface of the thermal conductive insulator is flat and smooth, and has good adhesion. It is widely used in industries such as electronics and electrical appliances.

Thermal conductive insulator is used in power equipment, communication equipment, consumer electronics, security equipment, LED lamps and other fields.

Features and Advantages

- Thermal conductivity of Fehonda Thermal Conductive Insulator: 0.8-1.6W/mK

- High thermal conductivity, high insulation, low thermal resistance

- Smooth surface, easy to install, high reliability in long-term use

- UL94 V-0 flame retardant, meets RoHS environmental protection requirements

Thermal Conductive Phase Change Material

Thermal conductive phase change material is a new type of material made of nano-grade high thermal conductive filler and phase change compound. It is used for the heat transfer interface between power consumption devices and heat sinks.

The state of the material changes at 52°C, from solid to liquid. Liquid thermal conductive phase change material can fully wet the surface of power-consuming devices and heat sinks to form an excellent heat conduction channel. It can also be used to achieve optimal heat dissipation performance of the heat sink and enhance the reliability of power devices.

Thermal conductive phase change material has a wide range of applications, such as power semiconductor devices, solid-state relay bridge rectifiers, high-speed buffer memory chips, display chips, IGBT components, communication optical modules, microprocessors, memory modules, DC/DC converters, etc.

Features and Advantages

- Thermal conductivity of Fehonda thermal phase change material: 8.5W/mk

- Phase change occurs at 52℃, from solid phase to liquid phase

- Low thermal resistance, excellent thermal conductivity and heat dissipation performance, good reliability

- UL94 V-0 flame retardant, meets RoHS environmental protection requirements

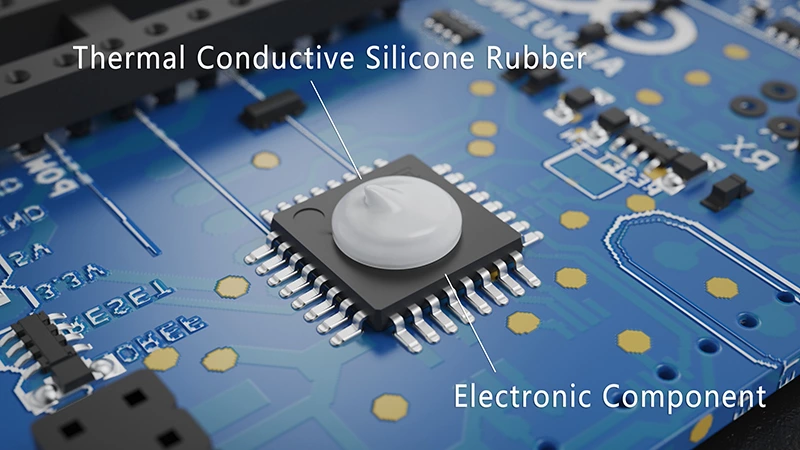

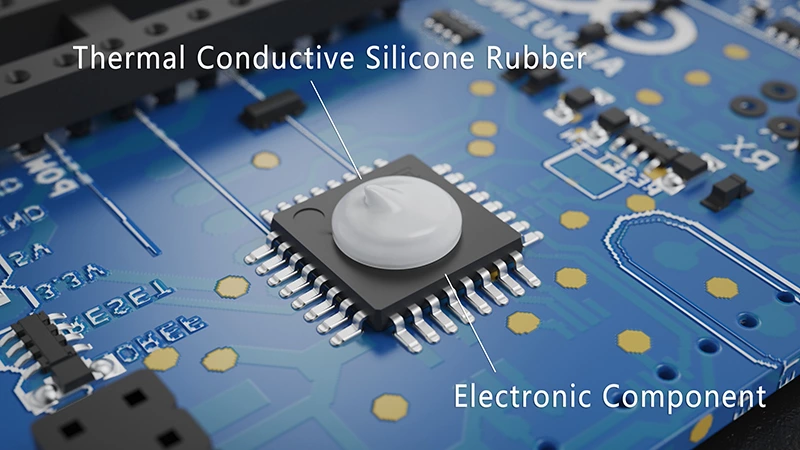

Thermal Conductive Silicone Rubber

Thermal conductive silicone rubber is a single-component, heat-conductive viscous liquid or paste-like silicone sealant that can cure at room temperature. Thermal conductive silicone rubber is mainly composed of polysiloxane, SiO2, aluminum oxide and other ingredients. It can combine with moisture in the air at room temperature to cause cross-linking, and then become a high-performance elastomer through vulcanization, which plays the role of heat conduction, insulation, bonding and sealing. It has good adhesion to many materials, such as metal, glass, ceramics, etc. In addition, it has the characteristics of anti-stretching, anti-vibration and anti-impact in a wide temperature range (-60~200℃), and is widely used in a variety of electronic components.

Features and Advantages

- Thermal conductivity of Fehonda thermal conductive silicone rubber: 1-3W/mK

- Resistance to hot and cold alternation, aging resistance, high electrical insulation

- Excellent moisture resistance, tensile resistance, shock resistance, weather resistance, and chemical resistance

- UL94 V-0 flame retardant, meets RoHS environmental protection requirements

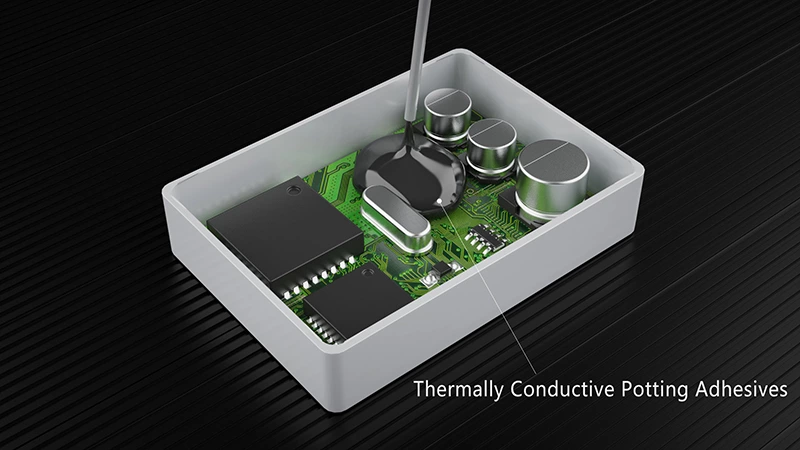

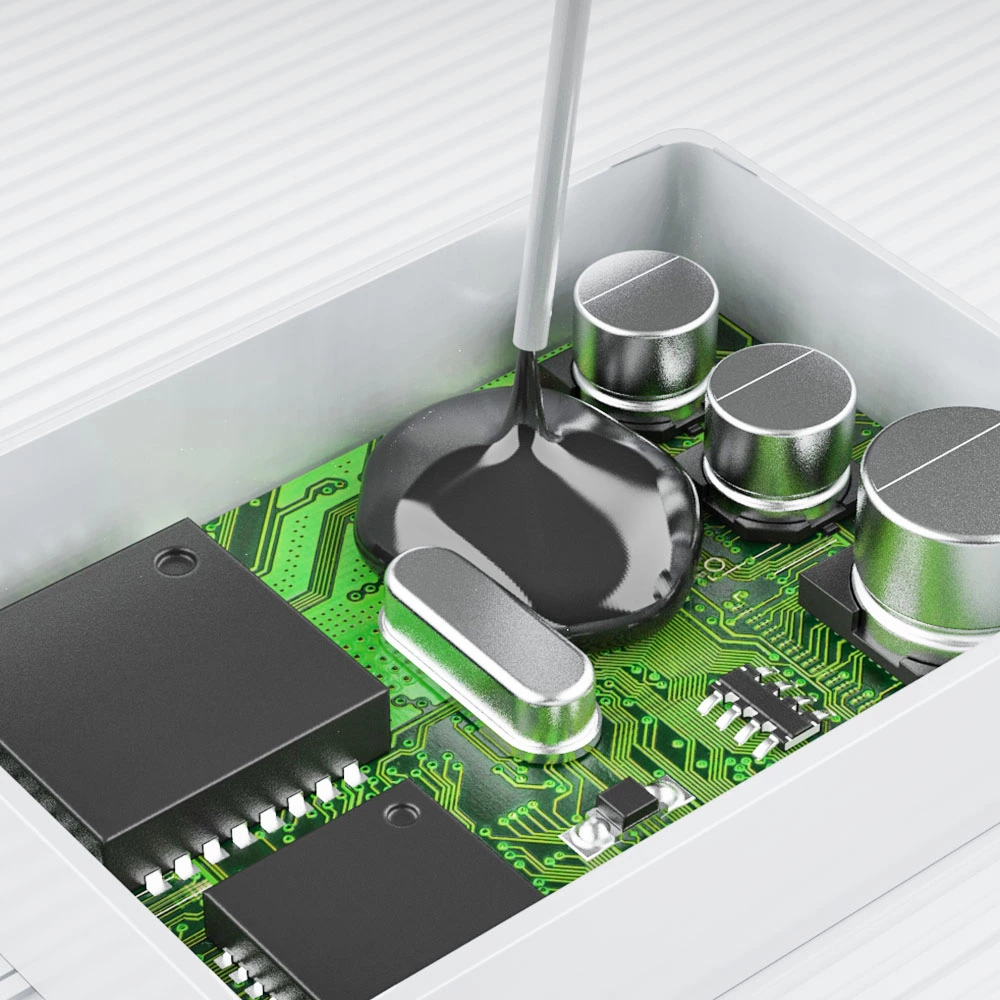

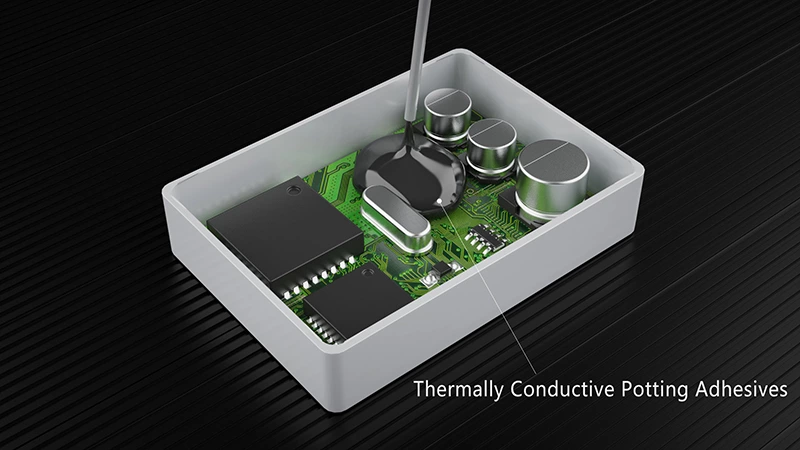

Thermally Conductive Potting Adhesive

Thermally conductive potting adhesive is a two-component polyurethane potting material with excellent electrical properties. It will not corrode electrical components and has good adhesion to metals such as steel, aluminum, copper, tin, and materials such as rubber, plastic, PET, PVC, and PC.

The cured potting material can protect the installed and debugged electronic components and circuits from vibration, corrosion, moisture and dust.

Features and Advantages

- Thermal conductivity of Fehonda thermally conductive potting adhesive: 0.6-1W/mk

- Low viscosity, easy to operate, temperature range: -60℃~135℃

- Excellent reliability such as aging resistance, acid and alkali resistance, corrosion resistance

- Excellent adhesion to materials such as metal, plastic, PET, PVC, PC

- Minimal internal stress, little damage to devices, protect electronic components

- UL94 V-0 flame retardant, meets RoHS environmental protection requirements

With the continuous advancement of science and technology, the demand for thermal conductive materials is also increasing. In the fields of new energy, aerospace, medical treatment, etc., people's demand for efficient thermal conductive materials is becoming more and more urgent. Researchers are working hard to develop new thermal conductive materials to meet the needs of future technological development. Let us look forward to thermal conductive materials opening a new chapter for future technological development!