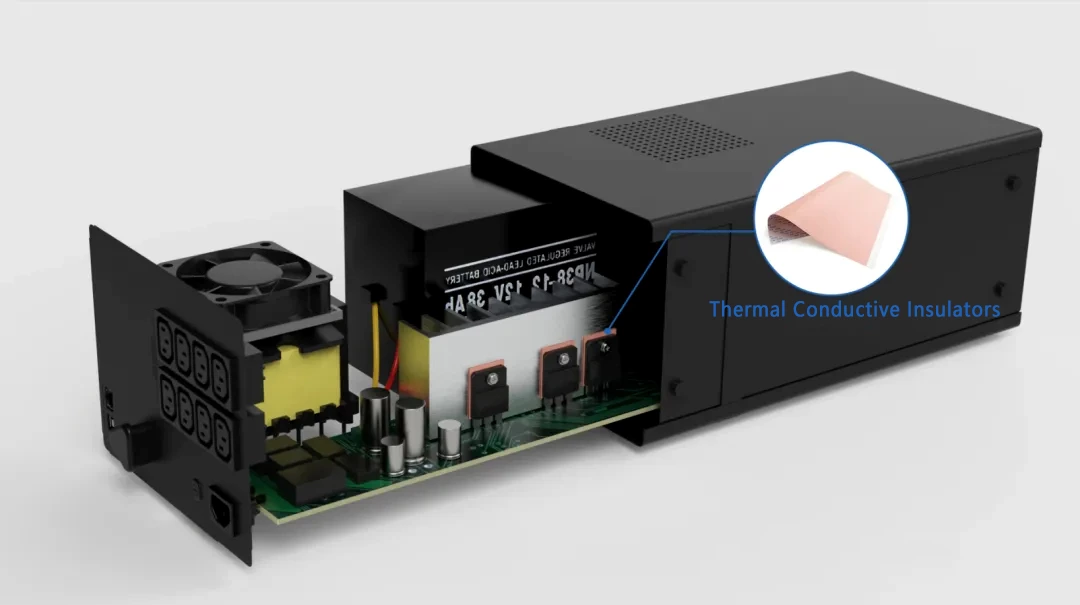

A thermal conductive insulator is an advanced composite material engineered from silicone rubber and glass fiber, designed to optimize heat dissipation while maintaining electrical insulation. This dual-function solution is critical for industries requiring precise thermal management in high-voltage environments, such as power electronics, automotive systems, and LED manufacturing.

What is a Thermal Conductive Insulator?

Key Features & Technical Advantages

-

Superior Thermal Conductivity

-

Thermal Conductivity Range: 0.8–1.6W/mK

-

Reduces thermal resistance by 30–50% compared to traditional materials.

-

Enhances heat transfer efficiency between components and heat sinks.

-

-

High Electrical Insulation & Safety

-

Dielectric Strength: >5kV/mm (prevents short circuits from metal part piercing).

-

UL94 V-0 Flame Retardant Certification & RoHS Compliance.

-

-

Industrial-Grade Durability

-

Smooth surface with low installation pressure for seamless integration.

-

Resists deformation under prolonged high-temperature operation.

-

-

Customization Flexibility

-

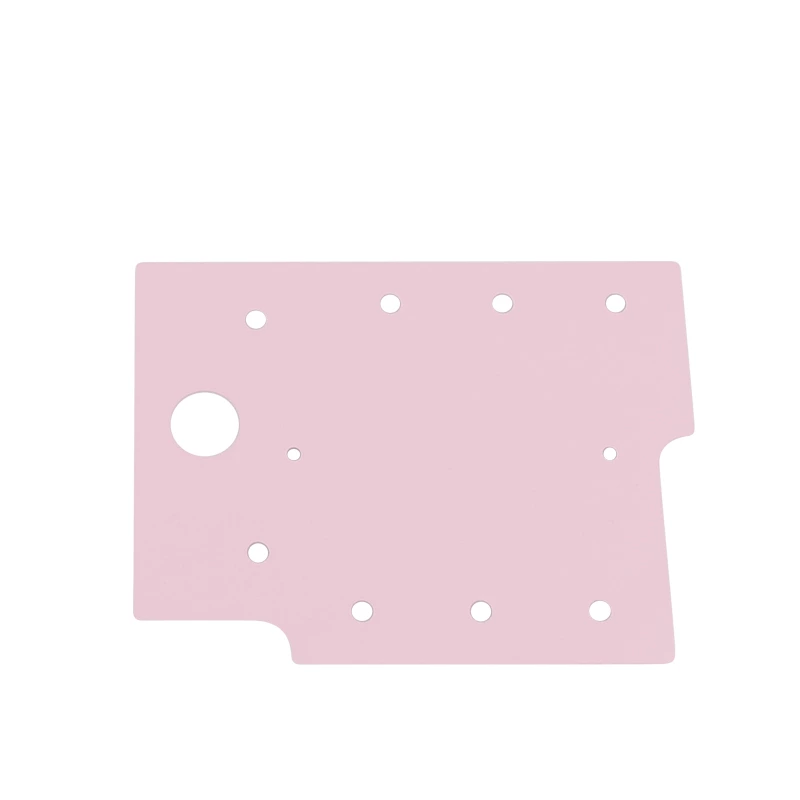

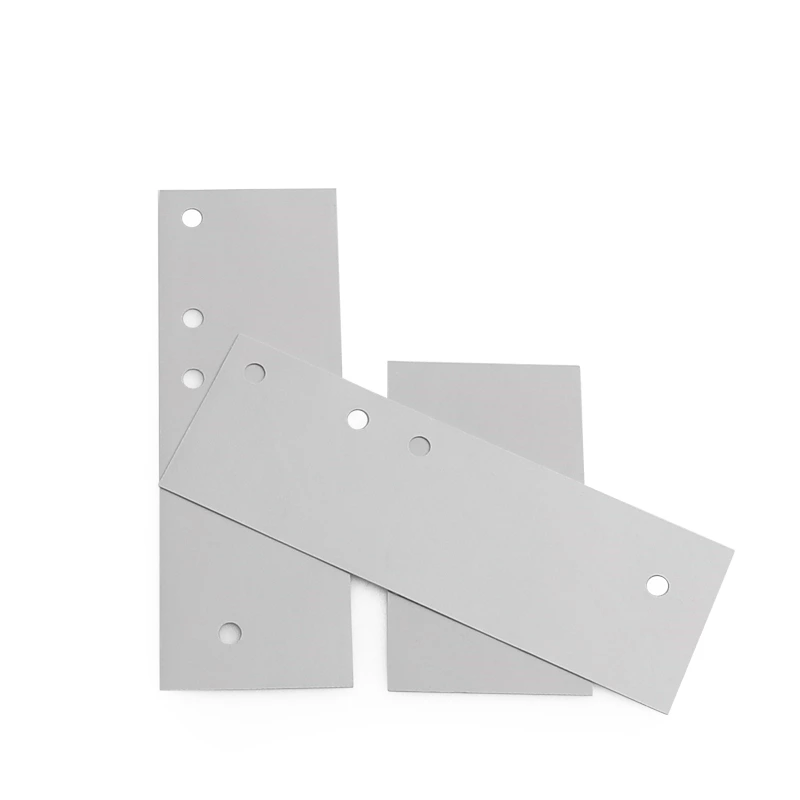

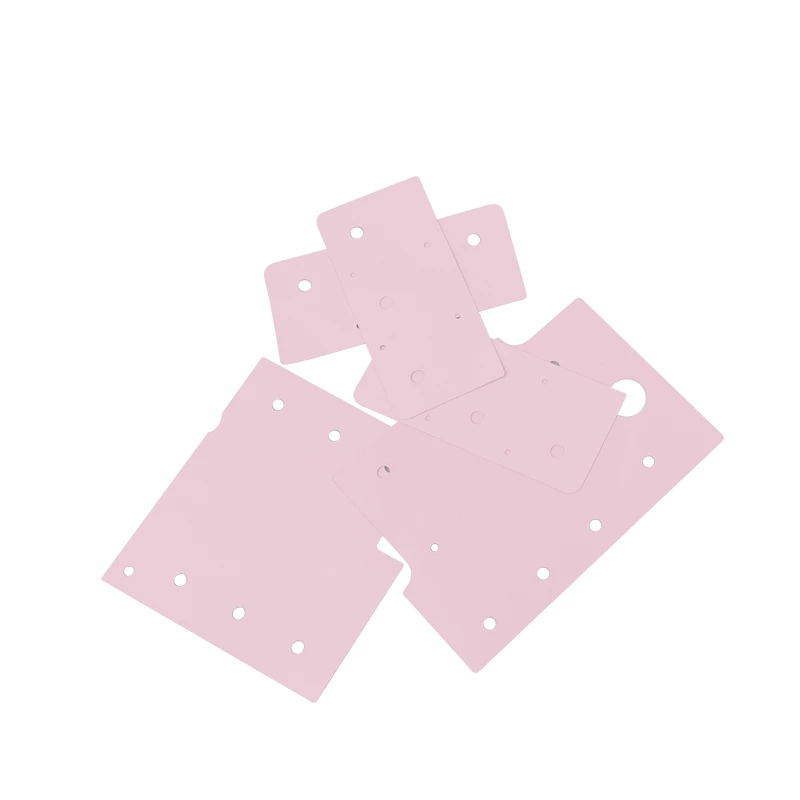

Colors: Pink, Gray, Yellow (corporate branding options).

-

Shapes: Precision die-cut sheets tailored to your CAD designs.

-

Industry Applications

Fehonda thermal conductive insulators are trusted by OEMs and industrial manufacturers for:

-

Power Electronics: MOSFETs, IGBT modules, inverters.

-

Telecom Infrastructure: 5G base stations, server cooling.

-

Consumer Electronics: Smartphone batteries, laptop chipsets.

-

LED Lighting: High-power LED heat dissipation.

-

Automotive: EV battery packs, onboard chargers.

Why Choose Fehonda?

-

18+ Years of Expertise: Specialized in thermal management for harsh environments.

-

Fast Prototyping: 3–5 days sample delivery with DFM support.

-

Bulk Order Capacity: Stable supply chain for 1000,000+ unit/month production.

-

Certifications: ISO 9001, UL, RoHS, REACH.

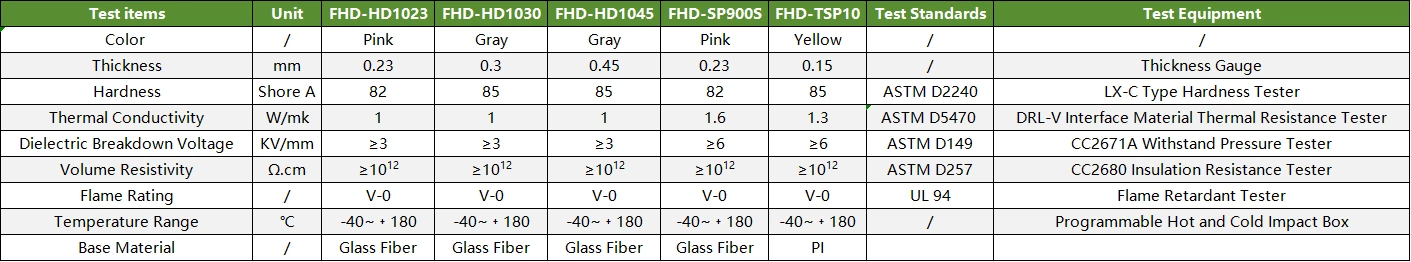

Technical Specifications Table

FAQs for Industrial Buyers

Q: Can this material withstand high-vibration environments?

A: Yes, the glass fiber reinforcement ensures mechanical stability in automotive/industrial applications.

Q: Do you provide material test reports (MTRs)?

A: Full documentation including thermal resistance curves and safety certifications available upon request.

Q: Minimum order quantity (MOQ) for custom shapes?

A: MOQ starts at 100 units with competitive bulk pricing.