Advantages of Two-Component Polyurethane Potting Adhesive

-

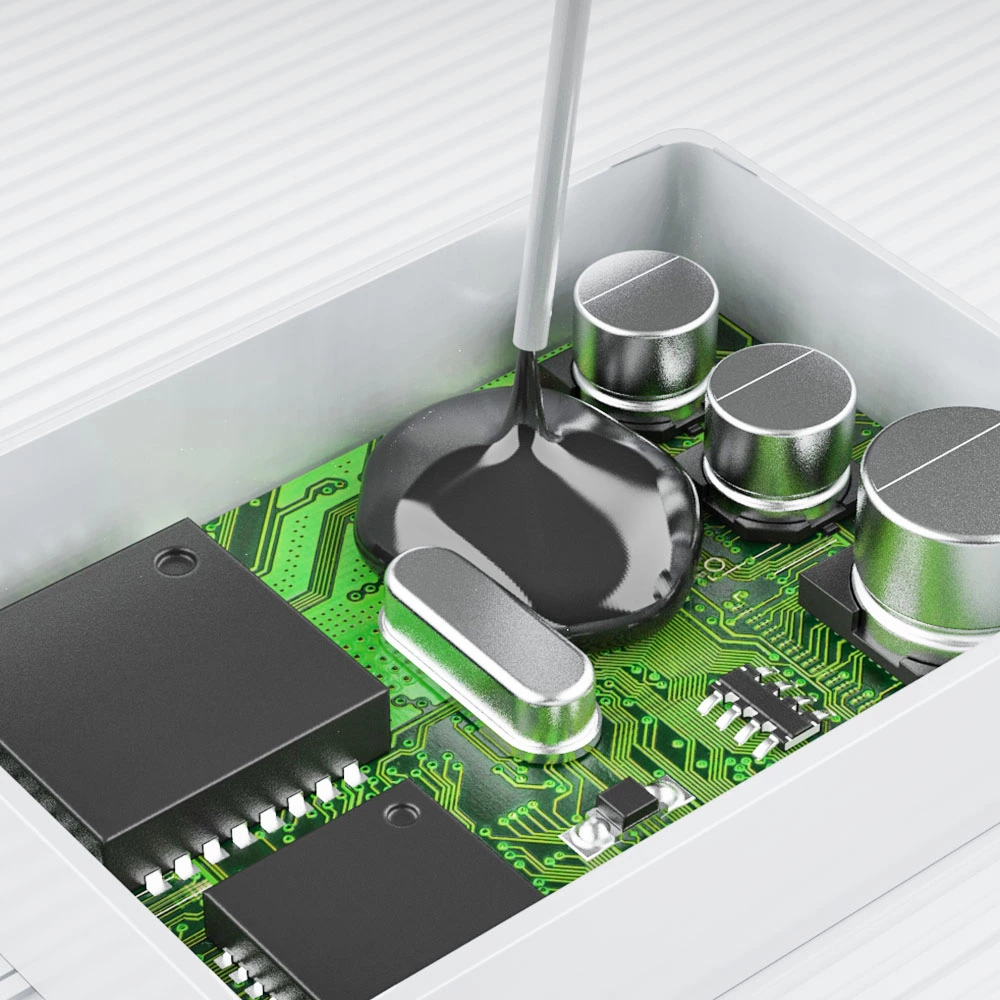

Excellent Protection: One of the key advantages of two-component polyurethane potting adhesive is its ability to provide excellent protection to electronic components against moisture, dust, chemicals, and mechanical stress.

-

Good Adhesion: This adhesive offers good adhesion to a wide range of substrates, including metals, plastics, and ceramics, ensuring a strong bond and effective sealing.

-

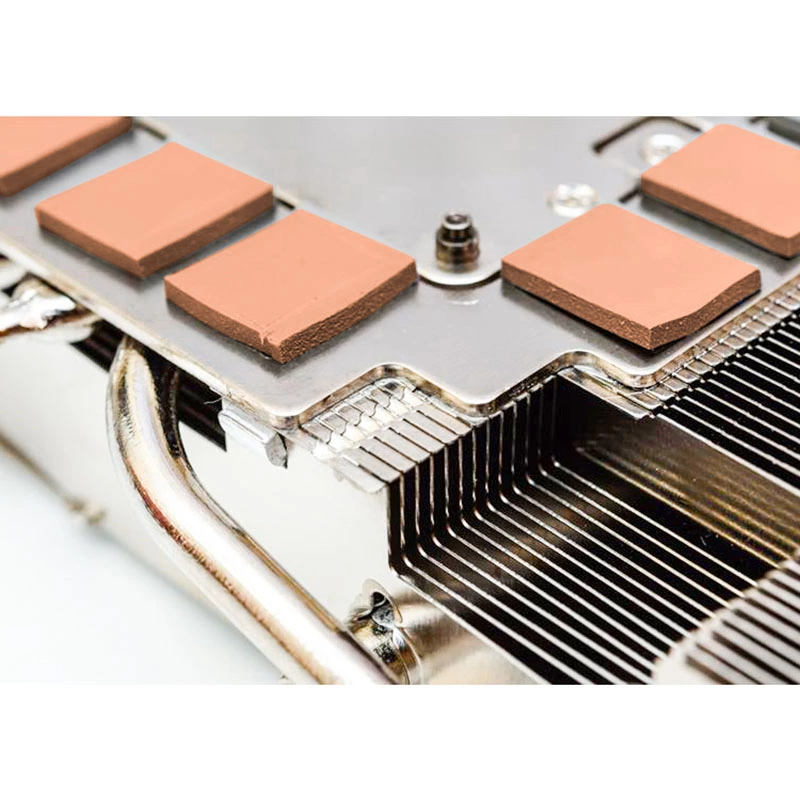

Thermal Stability: Two-component polyurethane potting adhesive exhibits high thermal stability, making it suitable for applications where temperature fluctuations are common.

-

Electrical Insulation: The adhesive provides electrical insulation properties, preventing short circuits and enhancing the overall performance and reliability of electronic devices.

-

Flexibility: It offers flexibility after curing, allowing for some degree of movement without compromising the protective seal around the components.

-

Chemical Resistance: Two-component polyurethane potting adhesive shows resistance to various chemicals, ensuring long-term durability even in harsh environments.

Applications of Two-Component Polyurethane Potting Adhesive

-

Electronics: This adhesive is widely used in the electronics industry for potting and encapsulating components such as circuit boards, sensors, and connectors to protect them from environmental factors and ensure long-term reliability.

-

Automotive: In the automotive sector, two-component polyurethane potting adhesive is utilized for sealing sensors, control modules, and electronic systems in vehicles to enhance their performance and durability.

-

Industrial Equipment: It finds applications in industrial equipment for potting electronic components in machinery, control panels, and sensors to safeguard them from harsh operating conditions.

-

Renewable Energy: Two-component polyurethane potting adhesive is commonly used in the renewable energy sector for encapsulating solar panels, wind turbines, and battery systems to protect critical components from weather elements.

-

Telecommunications: In the telecommunications industry, this adhesive is employed for potting cables, connectors, and communication devices to ensure reliable operation and longevity.

Materials Used in Two-Component Polyurethane Potting Adhesive

-

Polyol Component: This component typically consists of polyether or polyester polyols that provide the adhesive with flexibility, adhesion, and chemical resistance properties.

-

Isocyanate Component: The isocyanate component reacts with the polyol component to form a crosslinked network, offering strength, durability, and thermal stability to the adhesive.

-

Fillers and Additives: Various fillers such as silica, talc, or glass beads, along with additives like antioxidants and UV stabilizers, may be incorporated to modify the adhesive's properties and enhance its performance.

Factors to Consider When Using Two-Component Polyurethane Potting Adhesive

-

Curing Time: Understanding the curing time of the adhesive is crucial for planning production schedules and ensuring efficient manufacturing processes.

-

Mixing Ratio: The correct mixing ratio of the two components is essential to achieve the desired physical and chemical properties of the cured adhesive.

-

Environmental Conditions: Consideration of environmental factors such as temperature and humidity during application and curing can impact the performance of the adhesive.

-

Safety Precautions: It's important to follow safety guidelines when handling two-component polyurethane potting adhesive, including proper ventilation and protective equipment.

Conclusion

Two-component polyurethane potting adhesive offers a range of benefits, including excellent protection, thermal stability, and electrical insulation, making it a versatile choice for encapsulating and protecting electronic components in various industries. By understanding its advantages, applications, and key considerations, manufacturers can make informed decisions regarding the use of this adhesive in their production processes.