2.0W Thermal Pad

A thermal pad is a material designed to facilitate heat transfer between two surfaces, typically between a heat-producing component (like a CPU or GPU) and a heatsink or cooling solution. Thermal pads are usually made of silicone, metal oxides, or other thermally conductive materials and are used to fill the air gaps that exist between components.

The 2.0W in 2.0W thermal pads refers to the thermal conductivity of the pad, which is 2.0 Watts per meter Kelvin (W/m·K). This measurement indicates how effectively the material can conduct heat. The higher the value, the better the thermal pad is at transferring heat from one surface to another.

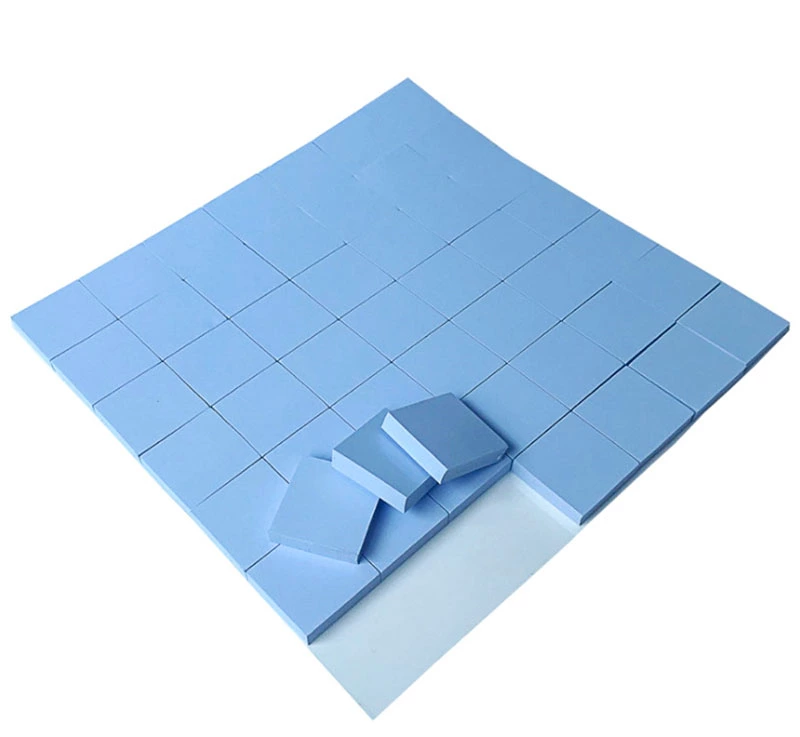

Self-adhesive on both sides, not easy to peel off, soft, good compressibility, high reliability in long-term use, can be used for heat transfer between semiconductors, power devices and housings or other heat sinks.

- Thermal Conductivity: 2.0 W/m.k

- Hardness:Shore C 20~45

- Thickness:0.5~6.0mm

- Breakdown Voltage:>6~10 Kv/mm

Why Choose a 2.0W Thermal Pad?

While there are various thermal pads available with different thermal conductivities, a 2.0W thermal pad offers a balanced combination of performance and cost-efficiency. Below are some key reasons why a 2.0W thermal pad is often the preferred choice in many applications:

1. Efficient Heat Dissipation

The 2.0W thermal pad offers an excellent level of heat transfer, making it ideal for use in devices that generate moderate amounts of heat. It ensures that the heat from critical components is efficiently conducted to a heatsink or cooler, preventing overheating and enhancing device stability.

2. Ideal for Consumer Electronics

Many consumer electronics, such as laptops, gaming consoles, smartphones, and desktops, utilize 2.0W thermal pads to manage heat effectively. These devices require a solution that balances heat dissipation without adding excessive cost or size. The 2.0W thermal pad fits perfectly into this niche.

3. Cost-Effective Solution

Compared to higher-performance thermal pads (like those with 5.0W or 10.0W thermal conductivity), the 2.0W thermal pad is more affordable, making it a great choice for budget-conscious manufacturers and DIY enthusiasts. It offers good performance without the high price tag of more specialized solutions.

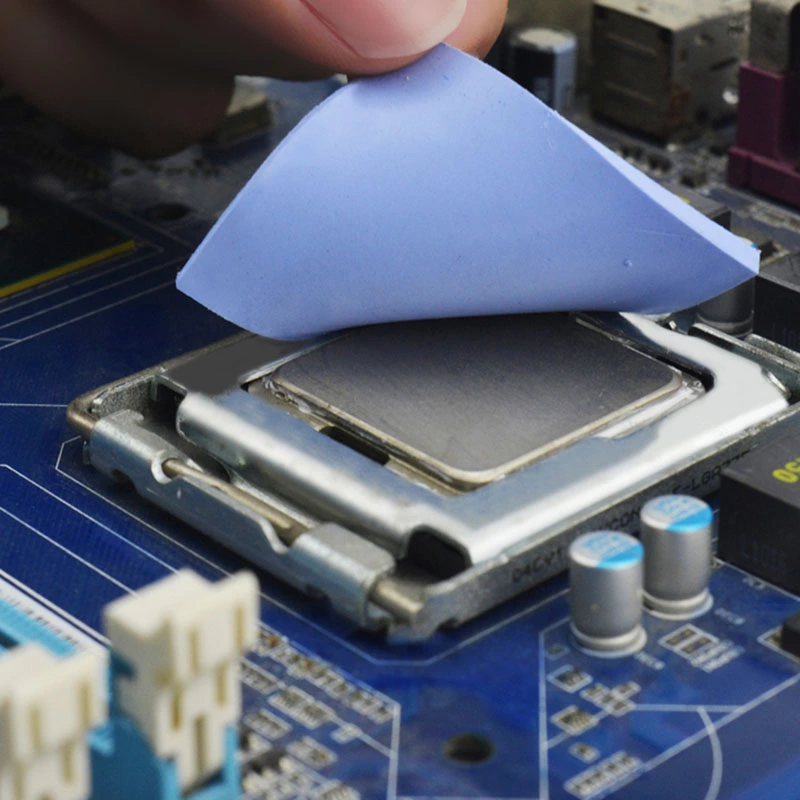

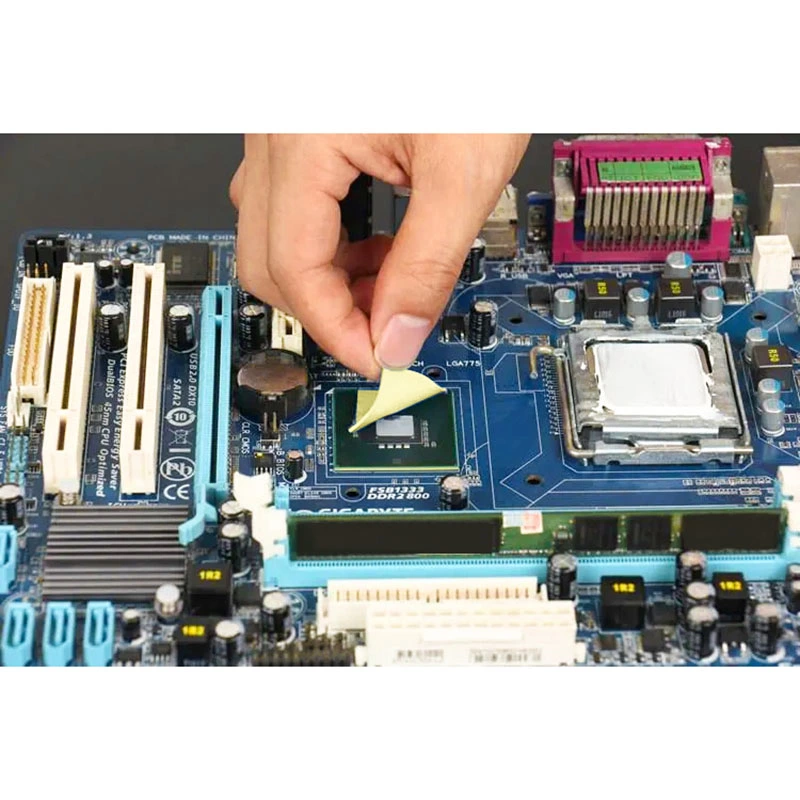

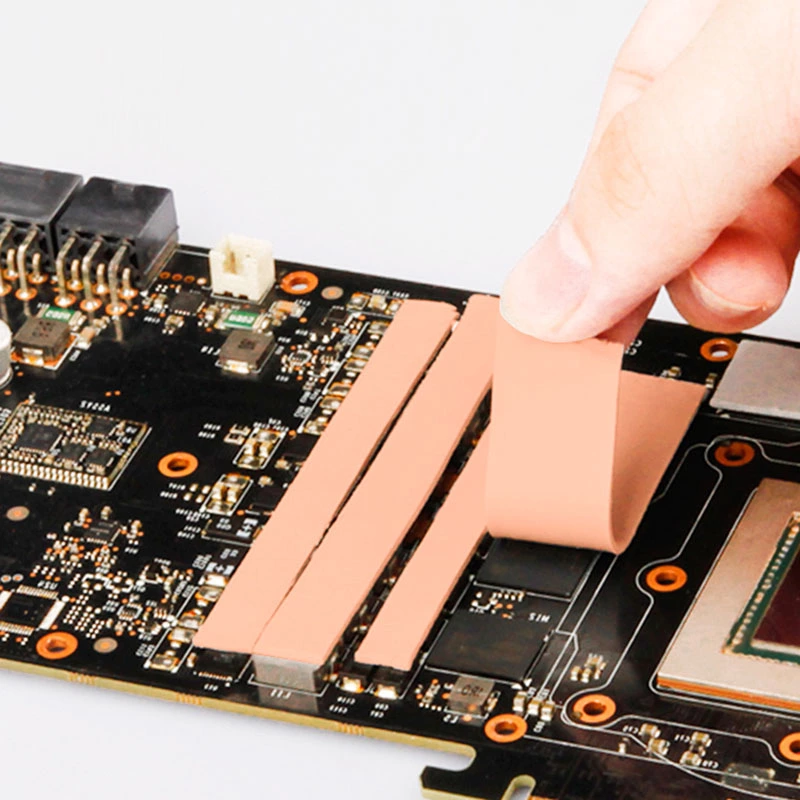

4. Easy to Use

Thermal pads are often easier to apply than thermal pastes, as they don’t require as much precision during application. A 2.0W thermal pad typically comes pre-cut to specific sizes, reducing the hassle of handling and applying. This makes it perfect for users who want a quick and efficient solution to heat management.

Benefits of Using 2.0W Thermal Pads

1. Improved Reliability and Longevity

By maintaining a consistent temperature, 2.0W thermal pads help prevent overheating, which can cause damage to delicate electronic components. Keeping devices within optimal temperature ranges ensures the longevity of the hardware, reduces the likelihood of thermal throttling, and prevents premature failure.

2. Enhanced Performance

When electronic components are properly cooled, they can perform more efficiently without the risk of thermal throttling. This results in better overall performance, especially in high-demand scenarios such as gaming, video editing, or heavy multitasking.

3. Easy Maintenance and Replacement

Thermal pads, unlike thermal paste, can be easier to replace and maintain. Since they are pre-formed and do not dry out over time, users can replace them without the mess associated with reapplying paste. A 2.0W thermal pad is durable and requires minimal maintenance, making it an excellent long-term solution for cooling.

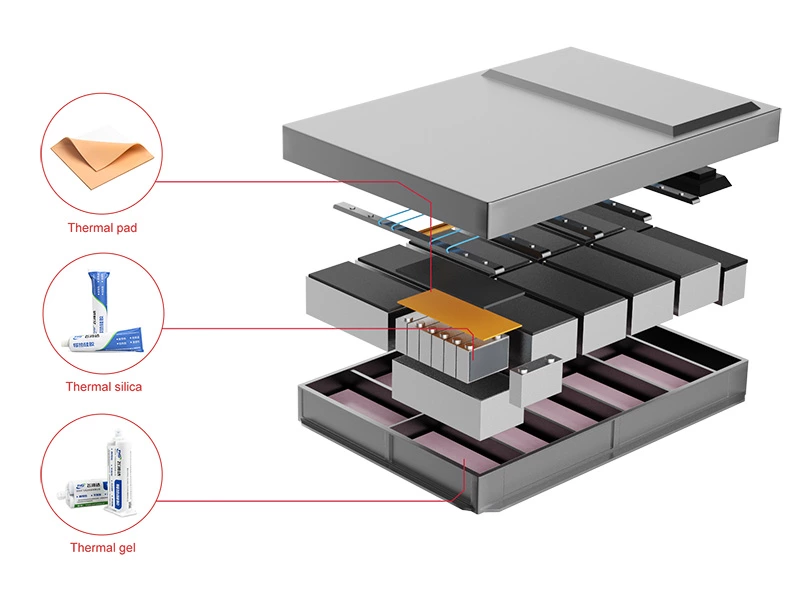

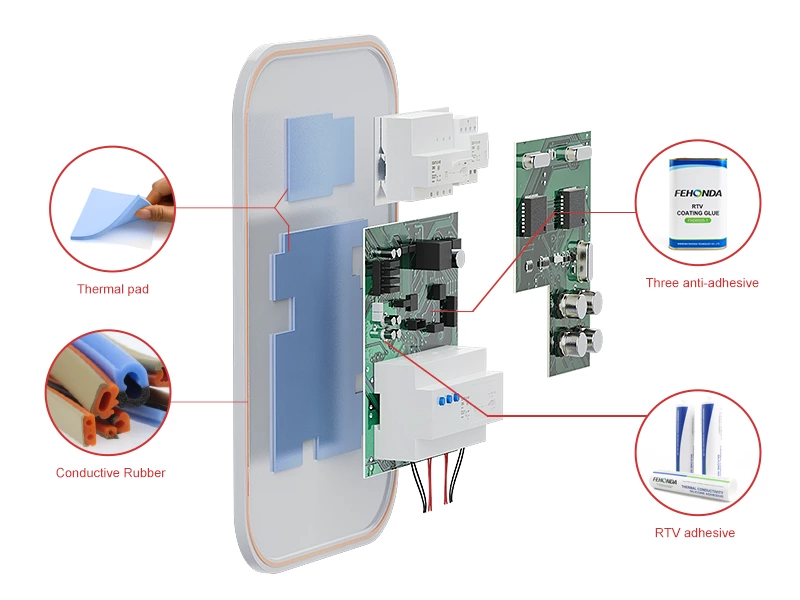

Applications of 2.0W Thermal Pads

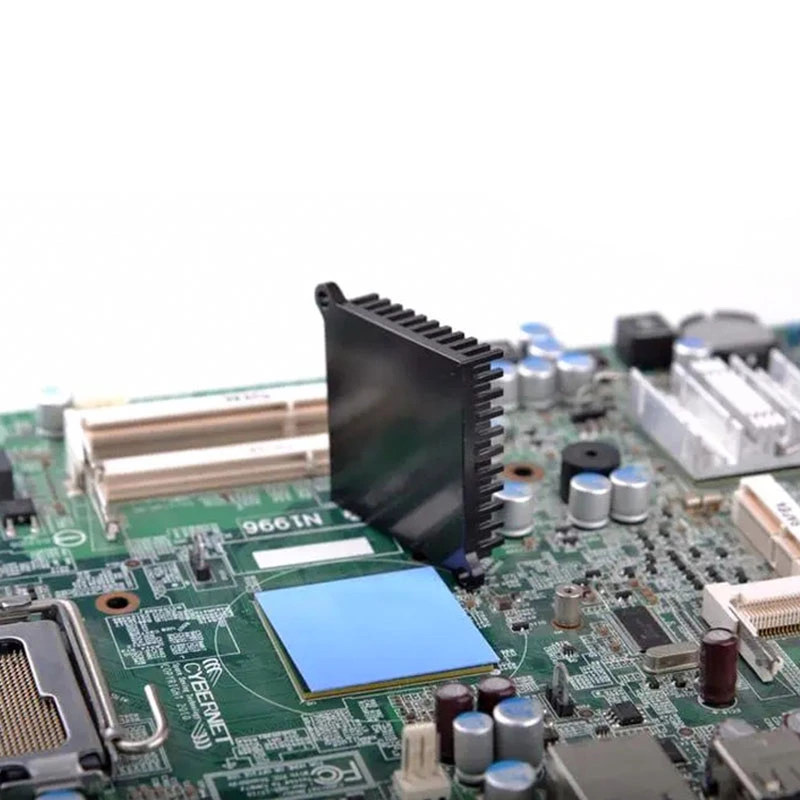

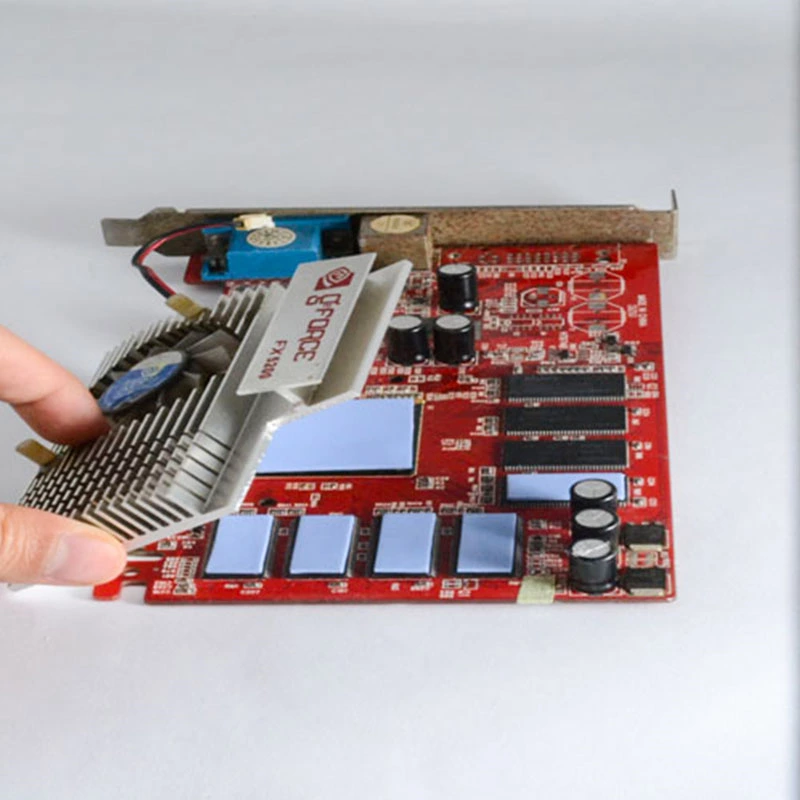

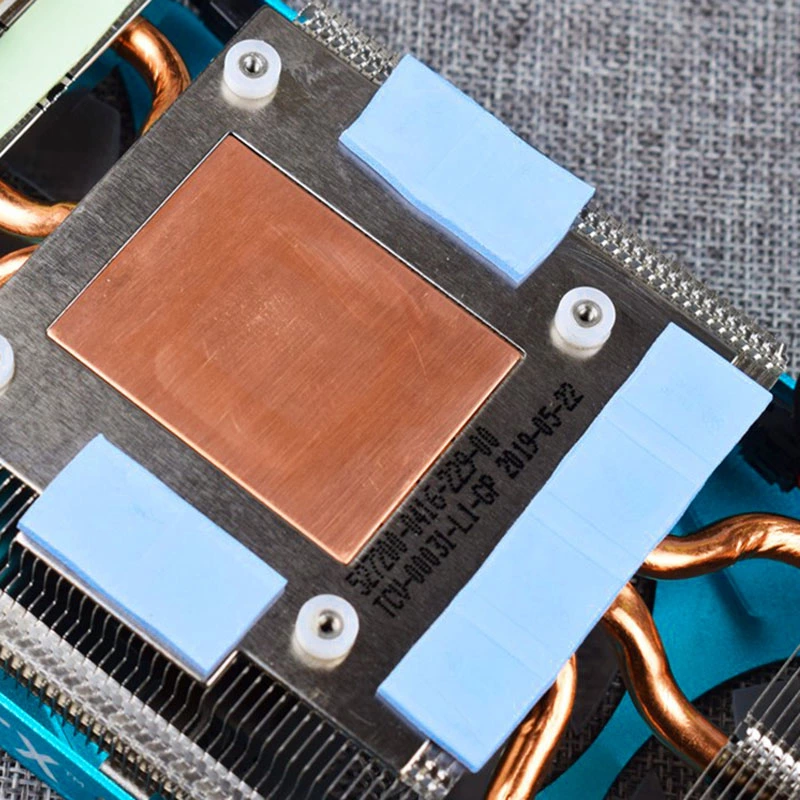

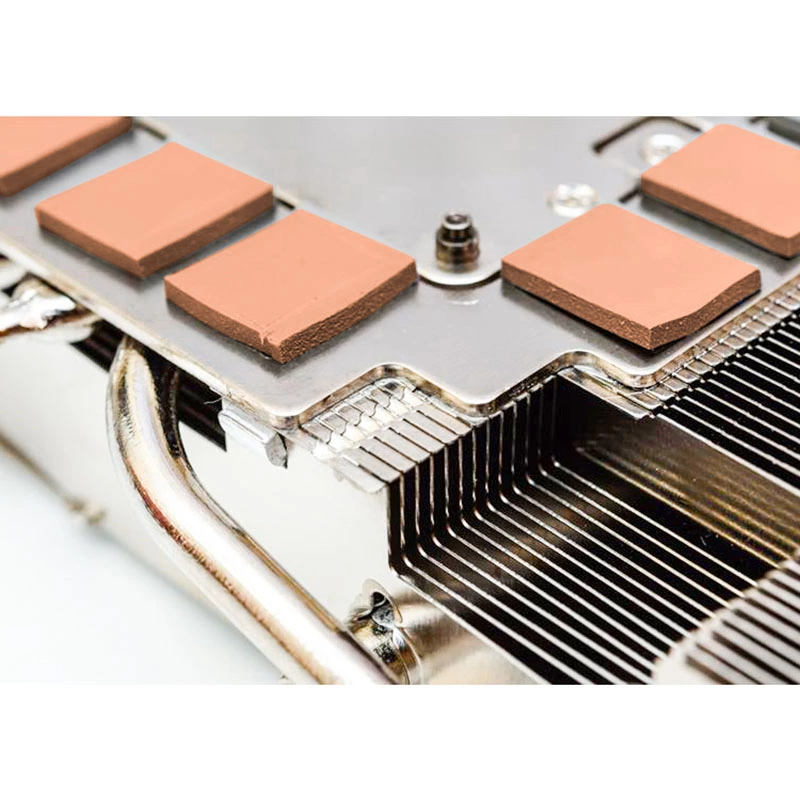

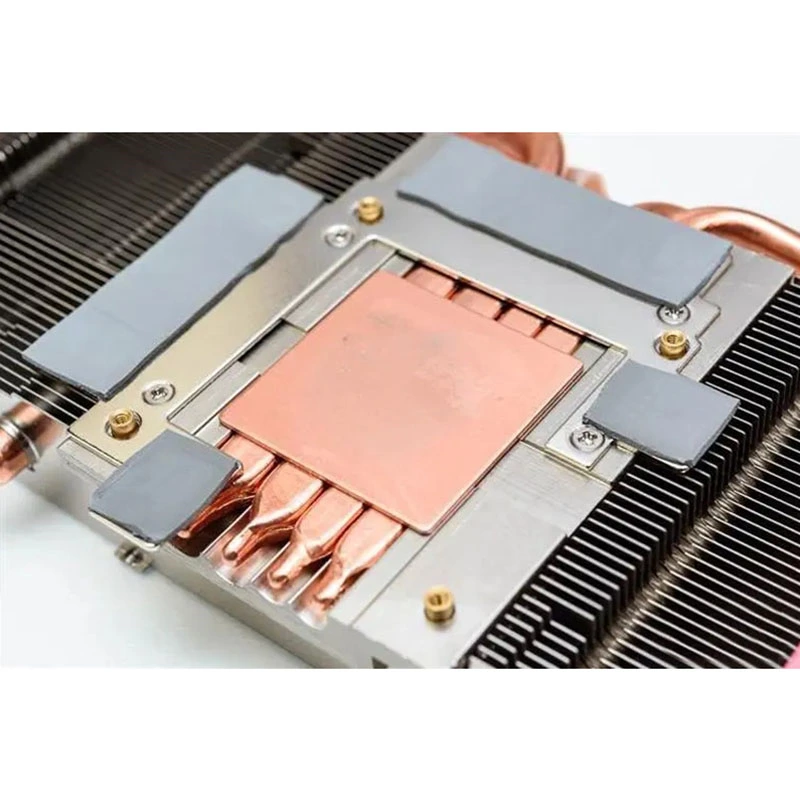

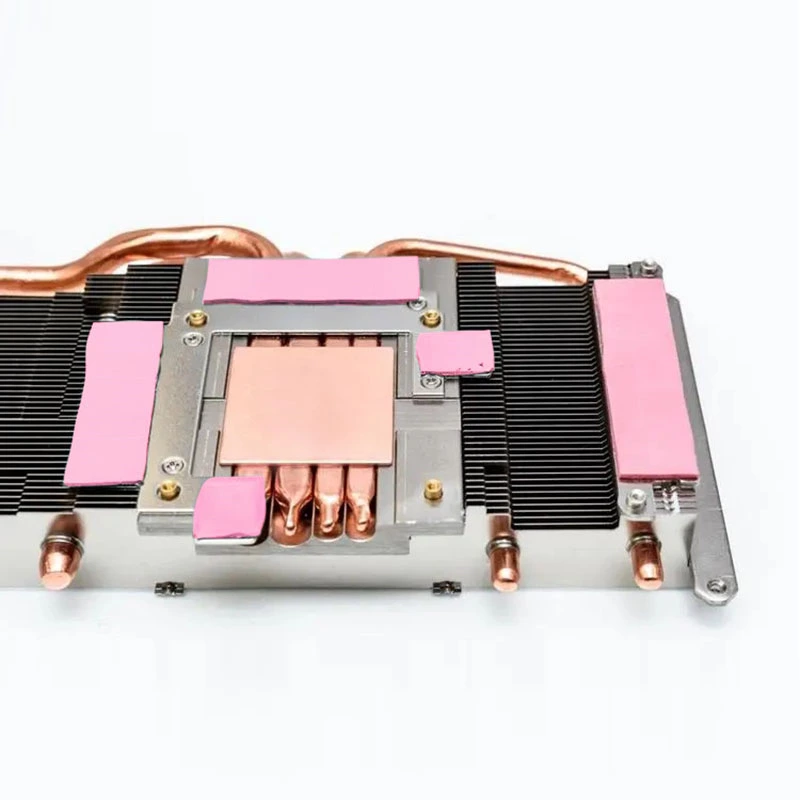

1. CPU and GPU Cooling

One of the primary applications of 2.0W thermal pads is in cooling CPUs (Central Processing Units) and GPUs (Graphics Processing Units). These components can generate significant heat, and a thermal pad is essential in transferring that heat away from the chip to a heatsink or fan system.

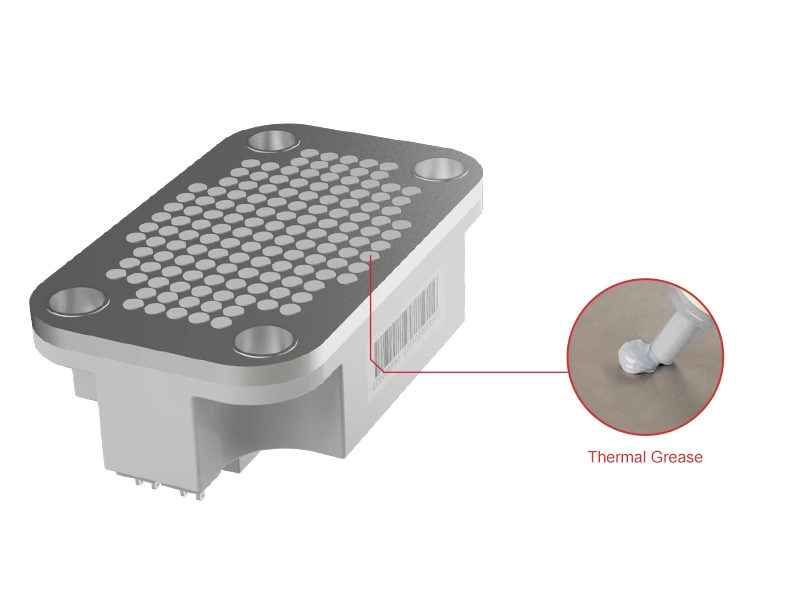

2. Power Electronics

Power electronic components such as voltage regulators, power transistors, and motor controllers often generate considerable heat. A 2.0W thermal pad provides an efficient way to conduct this heat to the cooling system, ensuring that these components function properly under load.

3. Consumer Electronics

As mentioned earlier, consumer electronics like laptops, desktops, smartphones, and gaming consoles all rely on thermal pads for efficient heat management. A 2.0W thermal pad is ideal for devices with moderate heat production, offering an affordable and effective solution for manufacturers and users alike.

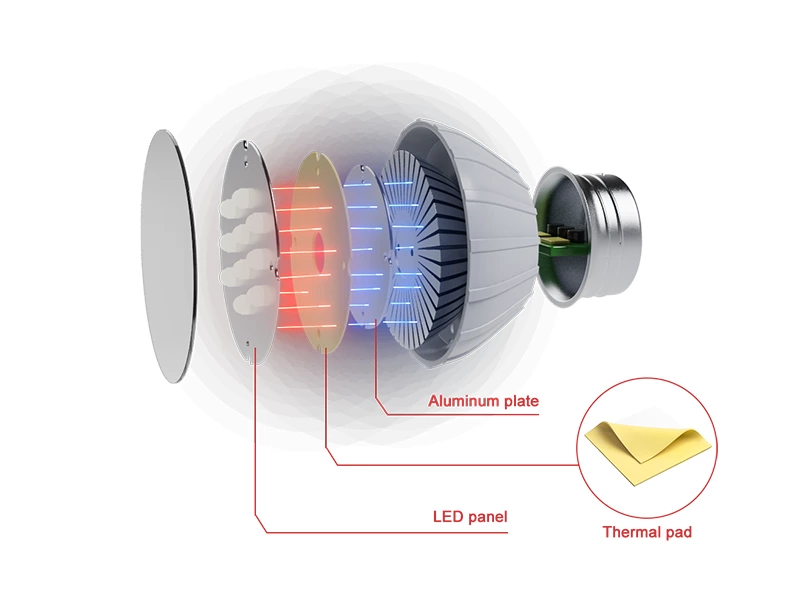

4. LED Lights and High-Power LED Modules

LEDs, especially high-power LEDs, require efficient heat dissipation to function properly and maintain a long lifespan. A 2.0W thermal pad is often used in these applications to ensure that heat is transferred away from the LED chips to prevent thermal damage.

How to Choose the Right Thermal Pad for Your Device

When selecting a thermal pad, it’s important to consider the specific needs of your device. Here are some factors to consider:

- Thermal Conductivity: If your device generates a lot of heat, you might need a thermal pad with a higher thermal conductivity (like 5.0W or more). For moderate heat production, a 2.0W thermal pad is usually sufficient.

- Size and Shape: Ensure that the thermal pad is the right size for your components. Some pads come in various sizes, while others can be cut to fit.

- Thickness: The thickness of the thermal pad can affect its performance. Thicker pads tend to offer better heat transfer but may not be suitable for all applications.

- Material: Make sure that the material of the thermal pad is compatible with your device. Silicone-based thermal pads are common, but some applications may benefit from graphite or other materials.

| Parameters | Unit | Regular | Low permeation Oil | Test Standard |

|---|---|---|---|---|

| Thermal Conductivity | W/m·k | 2.0 | 2.0 | ASTM D5470 |

| Hardness | Shore C | 20~45 | 20~45 | ASTM D2240 |

| Density | g/cc | 2.5±0.2 | 2.5±0.2 | ASTM D792 |

| Thickness | mm | 0.5~6.0 | 0.5~6.0 | ASTM D374 |

| Breakdown Voltage | Kv/mm | > 6 | > 6 | ASTM D149 |

| Volume Resistivity | Ω.cm | ≥10¹³ | ≥10¹³ | ASTM D257 |

| Silicone Permeability | % | ≤3 | ≤1 | 125°C/72h(compression50%) |

| Temperature Range | ℃ | -40~180 | -40~180 | / |

| Flame Rating | / | V-0 | V-0 | UL 94 |